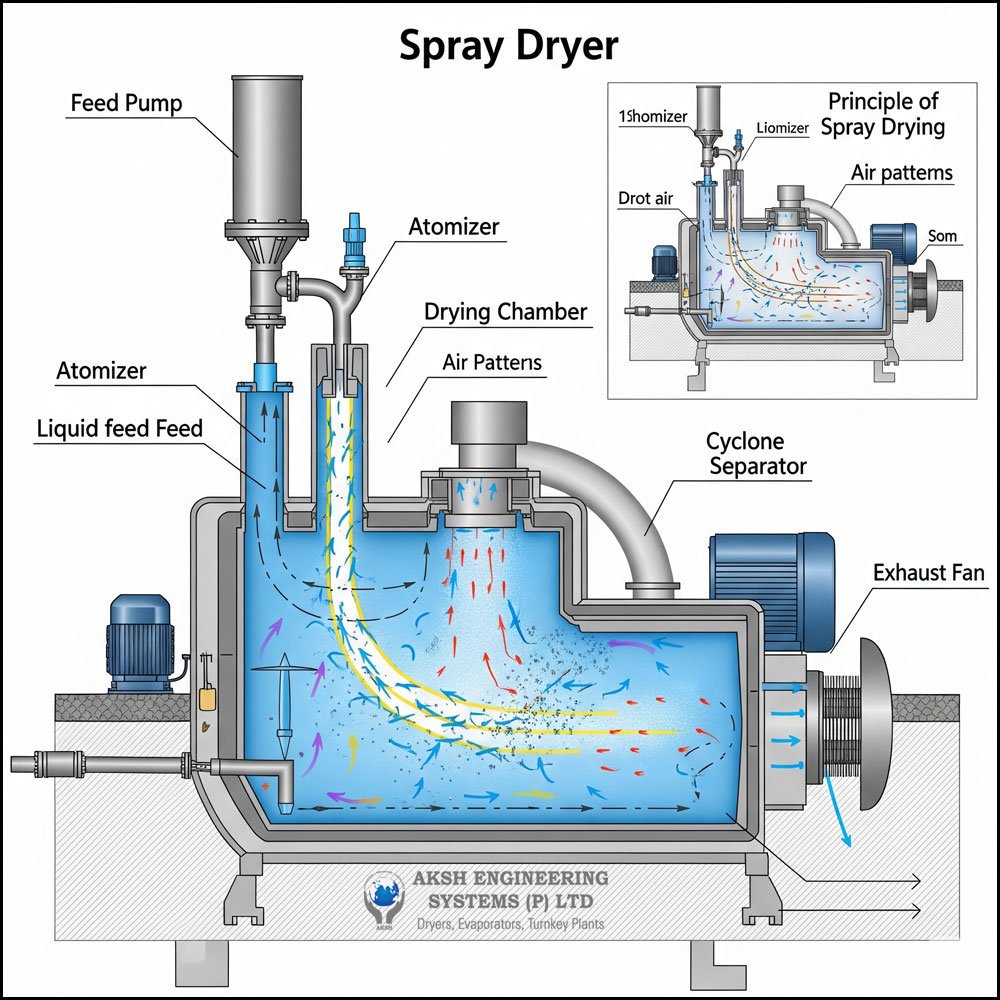

Key Components and Their Functions:

- Feed Pump: This initiates the process by precisely transferring the liquid feed from a holding tank to the atomizer. It ensures a consistent flow rate, which is crucial for uniform drying.

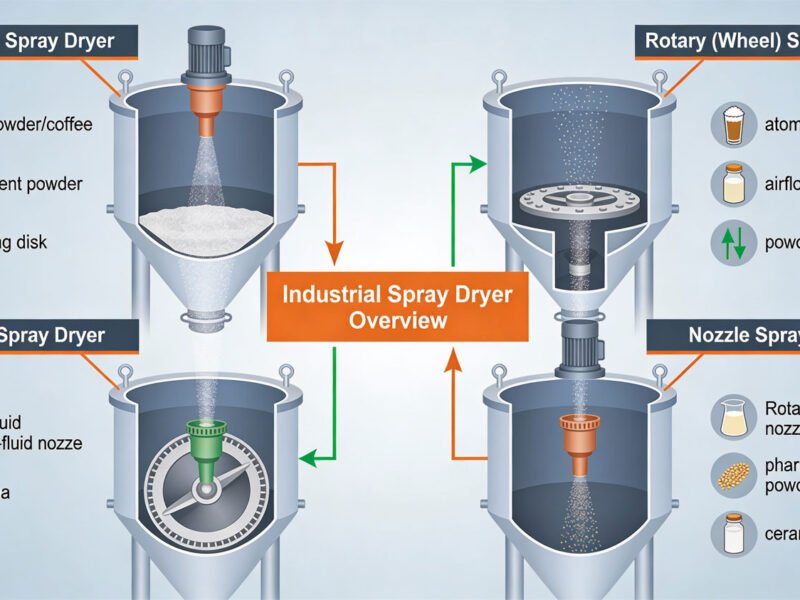

- Atomizer: This is arguably the most critical part of the spray dryer. Its function is to break the liquid feed into extremely fine droplets, maximizing the surface area for rapid drying. There are several types of atomizers, commonly:

- Nozzle Atomizers (Pressure or Two-Fluid): These use high pressure to force the liquid through a small opening or combine the liquid with a compressed gas (like air) to create a fine spray.

- Rotary Atomizers: These use a high-speed spinning disc to throw the liquid outwards, creating a thin film that breaks into droplets due to centrifugal force.

- Air Heater: This unit heats the incoming air to the desired drying temperature. The temperature and flow rate of this hot air are precisely controlled to ensure efficient moisture evaporation without degrading the product, especially for heat-sensitive materials.

- Air Disperser (Hot Air Inlet): This component ensures the hot air enters the drying chamber evenly and with a controlled flow pattern. The way the hot air and atomized droplets meet (co-current, counter-current, or mixed flow) influences the drying process and final product properties. In the diagram, it appears to be a co-current flow, where both the hot air and the sprayed liquid move in the same downward direction. This is often preferred for heat-sensitive materials because the wettest droplets immediately encounter the hottest air, leading to rapid surface cooling and protecting the core of the particle.

- Drying Chamber: This is the main body where the actual drying takes place. The atomized droplets come into contact with the hot air, and the moisture rapidly evaporates, leaving behind dry solid particles. The size and shape of the drying chamber are designed to allow sufficient residence time for the droplets to dry completely.

- Powder Discharge: At the bottom of the drying chamber, the majority of the dried powder, being heavier, falls down and is collected. This is the primary collection point.

- Cyclone Separator: Not all dry particles fall directly to the bottom. Some fine particles remain entrained in the exhaust air. The cyclone separator uses centrifugal force to separate these remaining dry particles from the air stream. The air-powder mixture enters the cyclone tangentially, creating a vortex. The heavier powder particles are thrown against the walls and slide down to a collection point, while the cleaner air exits from the top.

- Exhaust Fan: This fan draws the moist, cooled air out of the drying chamber and through the cyclone separator. It maintains the necessary airflow and slight negative pressure within the system for continuous operation.

- Exhaust Air Outlet (with Bag Filter): After the cyclone, there might be a final filtration step, often using a bag filter (not explicitly labeled as a separate unit in this diagram but implied by the “Exhaust Fan” pushing air out), to capture any remaining fine particles and ensure the air released to the atmosphere meets environmental standards.

The Spray Drying Process (Simplified Flow):

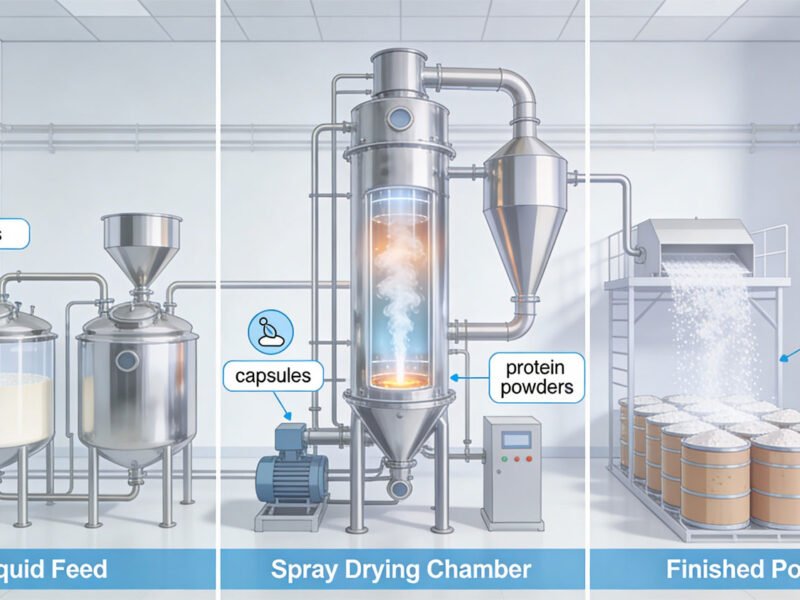

- Feed Preparation: The liquid material to be dried is prepared, often involving mixing, pre-heating, or homogenization.

- Atomization: The feed pump pushes the liquid to the atomizer, which converts it into a fine mist of droplets.

- Drying: Hot air from the air heater is introduced into the drying chamber, where it mixes with the atomized droplets. The heat rapidly evaporates the moisture from the droplets.

- Separation: The dried powder particles, now much lighter, are separated from the moist air. Larger particles fall to the bottom of the drying chamber, while finer particles are carried with the air into a cyclone separator.

- Collection: The collected dry powder is discharged for further processing or packaging.

- Exhaust: The remaining moist air, after particle separation, is expelled from the system by the exhaust fan.

Principle of Operation:

The core principle of spray drying is rapid and efficient heat and mass transfer. By atomizing the liquid into tiny droplets, the surface area for evaporation is vastly increased. When these droplets encounter the hot drying medium (usually air), the moisture quickly evaporates, leaving behind solid particles in a matter of seconds. This rapid drying process is particularly advantageous for heat-sensitive materials, as the short exposure time to high temperatures minimizes product degradation.

Applications:

Spray drying is widely used across various industries:

- Food Industry: Milk powder, instant coffee, fruit juice powders, egg powder, flavors, seasonings.

- Pharmaceutical Industry: Antibiotics, enzymes, vaccines, drug formulations (for enhanced stability, solubility, and bioavailability).

- Chemical Industry: Pigments, dyes, detergents, catalysts, ceramics, polymers.