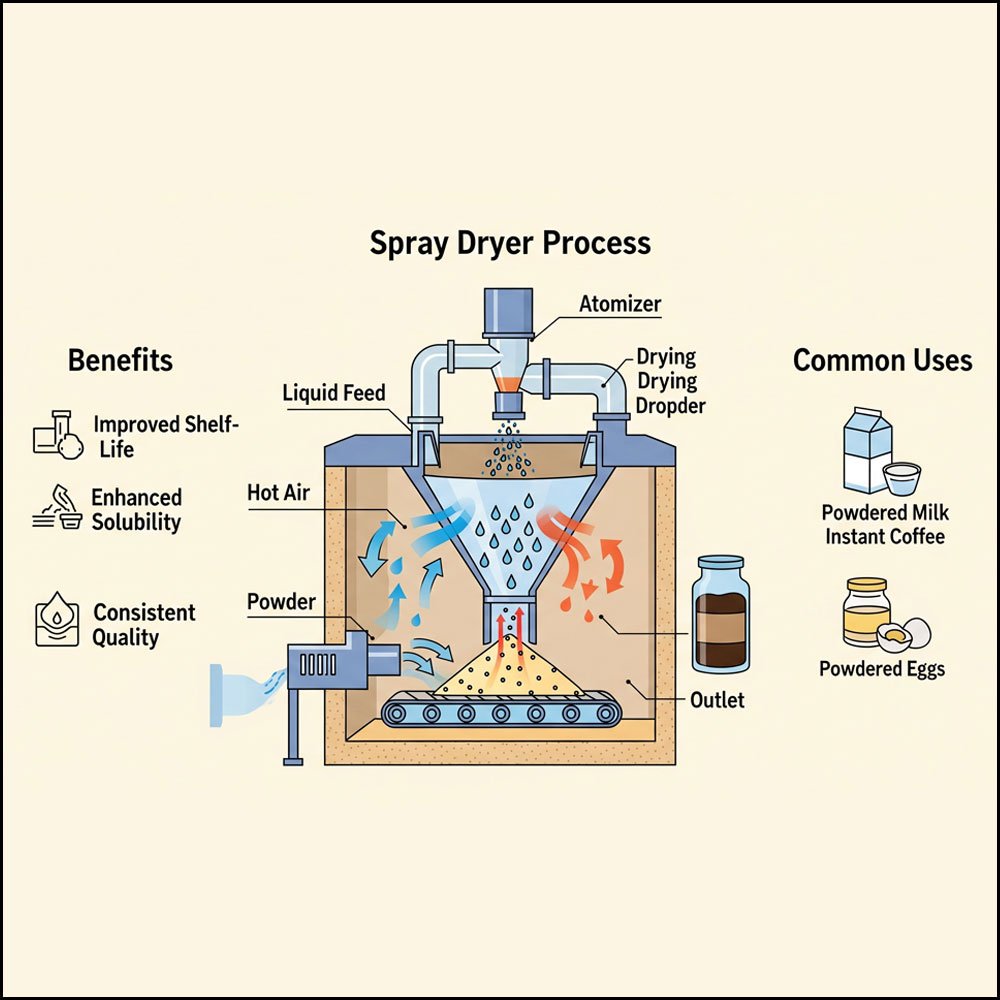

Spray drying is a vital technology in the food industry used to convert liquid food products into dry powders efficiently. This method offers numerous advantages that help food manufacturers produce high-quality, shelf-stable products while preserving nutritional value and flavor. Here’s an overview of the benefits and common applications of spray drying in food production:

Benefits of Spray Drying in the Food Industry

- Preservation of Nutritional Quality

Spray drying rapidly removes moisture at controlled temperatures, minimizing nutrient loss and preserving vitamins, minerals, and flavors in sensitive food ingredients. - Extended Shelf Life

By reducing moisture content to very low levels, spray-dried powders inhibit microbial growth and spoilage, significantly extending product shelf life without the need for refrigeration. - Consistent Product Quality

The controlled drying process yields powders with uniform particle size and moisture content, ensuring consistent texture, solubility, and reconstitution characteristics that are important for food quality and consumer satisfaction. - Efficient and Scalable Production

Spray drying is a continuous process that easily adapts to various production scales, from small batches to industrial volumes, enhancing manufacturing flexibility and cost efficiency. - Ease of Storage and Transport

Powdered food products are lightweight and occupy less space than liquids, reducing transportation costs and simplifying handling, which benefits manufacturers and consumers. - Versatility

Spray drying can process a wide range of food products, including dairy, fruits, vegetables, coffee, flavors, and proteins, supporting diverse food applications. - Improved Safety and Hygiene

The closed system minimizes contamination risks and meets stringent food safety standards.

Common Uses of Spray Drying in the Food Industry

- Milk Powder and Dairy Products: Spray drying transforms liquid milk into powder, making it easier to store, transport, and use in various food formulations.

- Instant Coffee and Tea Powders: The technology ensures preservation of flavor and aroma while creating granulated powders that dissolve quickly.

- Fruit and Vegetable Powders: Used in snacks, baking, and supplement formulations, these powders maintain most of the nutritional properties of fresh produce.

- Flavorings and Spices: Spray drying encapsulates flavors and aromatic compounds, allowing for controlled release and longer shelf life.

- Protein Powders and Nutritional Supplements: Spray drying is used to produce high-quality protein and vitamin powders with consistent properties and bioavailability.

Spray drying’s ability to combine quality preservation with production efficiency makes it indispensable in the modern food industry. The technology enhances product stability, convenience, and safety, meeting both manufacturing and consumer demands.