Spray drying is a widely used industrial process that transforms liquid feedstocks, such as solutions, suspensions, or emulsions, into dry powder form rapidly and efficiently. This technology is essential across many industries including food, pharmaceuticals, and chemicals, especially when dealing with heat-sensitive materials.

What Is a Spray Dryer?

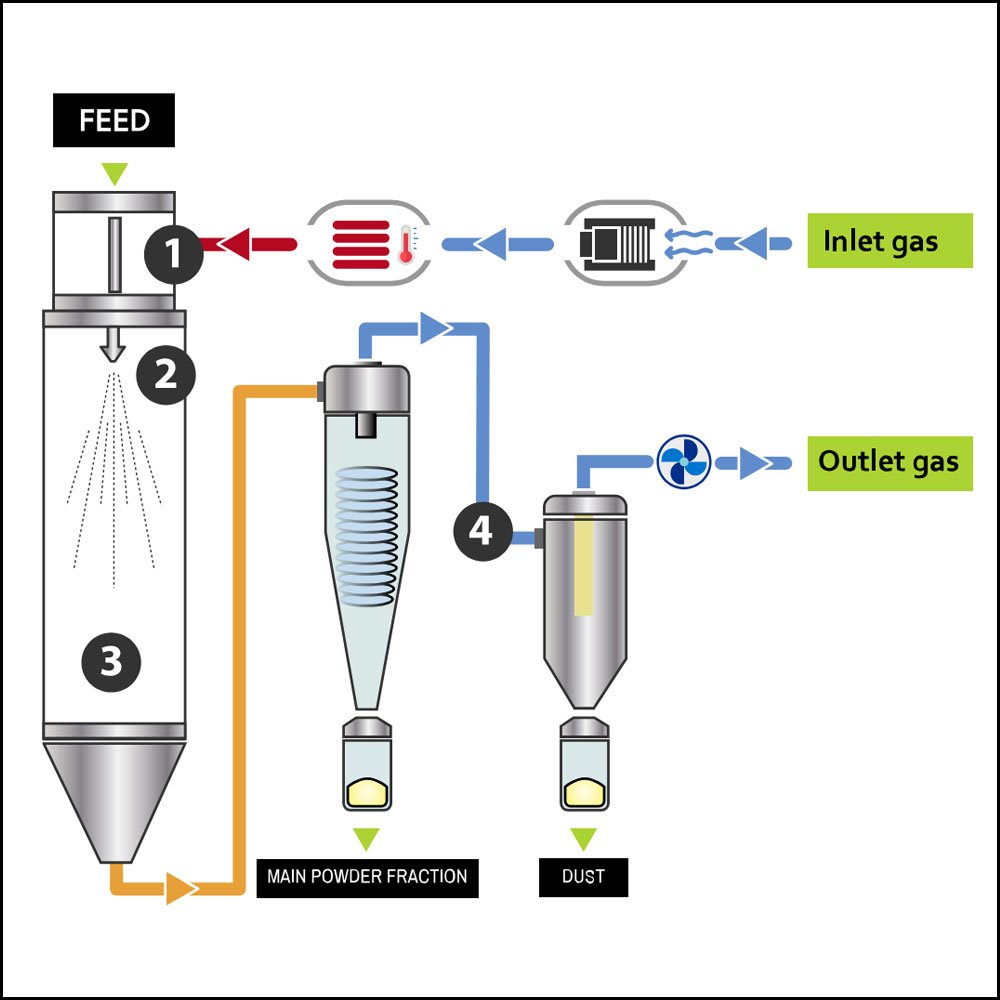

A spray dryer is a piece of equipment designed to convert a liquid or slurry into a dry powder in one continuous step. It works by atomizing the liquid into fine droplets and exposing them to a hot drying medium, usually air, causing rapid evaporation of moisture.

How Does a Spray Dryer Work?

The spray drying process typically involves three main stages:

- Atomization

The liquid feed is first broken down into tiny droplets using an atomizer or spray nozzle. This creates a large surface area to facilitate quick drying. Atomization methods include:- Pressure nozzles that force liquid through a small orifice at high pressure.

- Rotary atomizers that use high-speed spinning disks.

- Two-fluid nozzles that use compressed gas to produce fine droplets.

- Drying

These droplets are introduced into a drying chamber where they come into contact with hot air, often heated between 150°C and 300°C. The heat rapidly evaporates the moisture from the droplets, transforming them into solid particles. The drying happens so quickly that heat-sensitive products maintain their quality and properties. - Particle Separation and Collection

The dried particles, now in powder form, are separated from the moist hot air and collected at the bottom of the drying chamber or in cyclone separators. The exhaust air is filtered and released in an environmentally compliant manner.

Why Use Spray Drying?

Spray drying offers several key advantages:

- Rapid drying minimizes heat exposure, protecting delicate materials.

- Continuous operation allows for high production efficiency.

- Control over particle size and moisture content results in uniform, high-quality powders.

- Versatility enables drying of a wide range of liquid feeds, including pharmaceuticals, food ingredients, and chemicals.

Common Applications

- Food industry: milk powder, coffee, flavors, egg powders

- Pharmaceutical industry: powdered drugs, vaccines, enzymes

- Chemical industry: detergents, polymers, catalysts

Spray drying technology is a powerful and efficient drying solution critical for producing consistent, stable powders from liquids. Its ability to preserve the integrity of heat-sensitive products while delivering high throughput makes it indispensable in modern manufacturing.