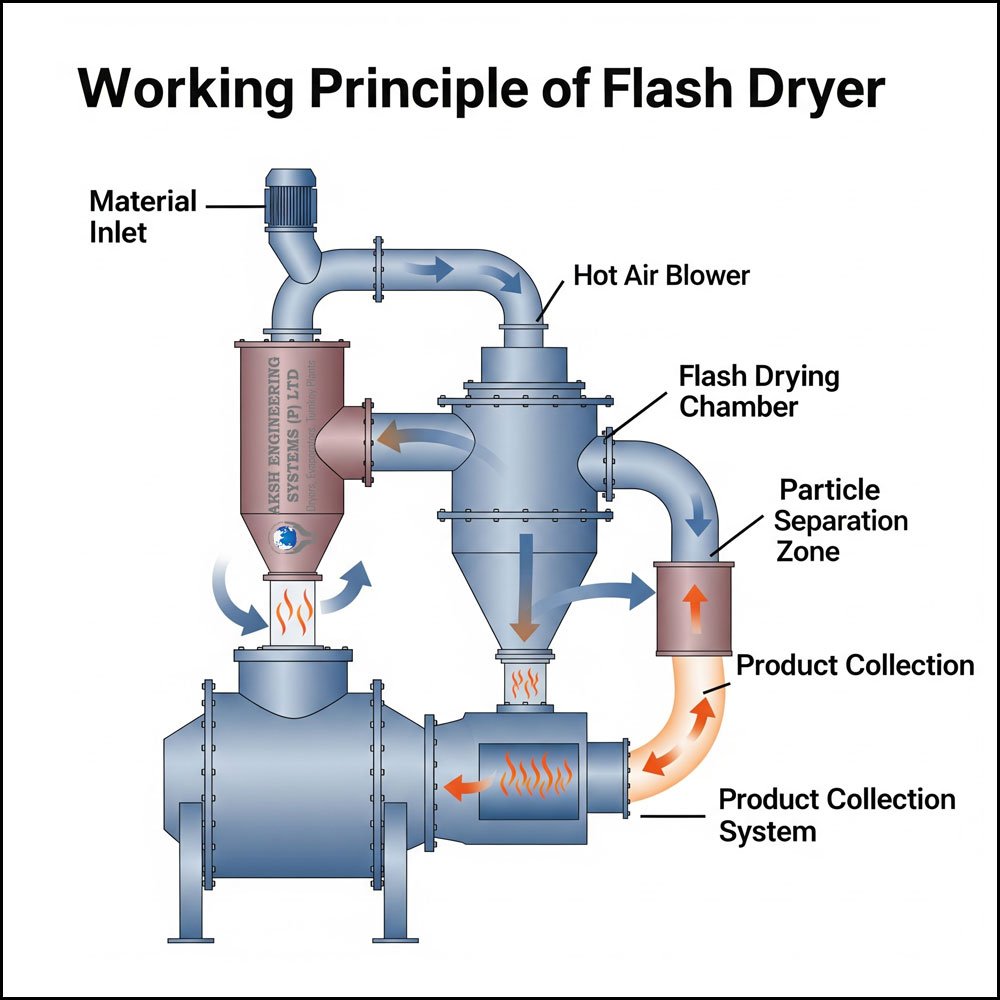

A flash dryer is a type of industrial dryer used for the rapid drying of moist, particulate materials. It operates on the principle of pneumatic conveying, where the material is suspended and conveyed in a stream of hot gas.

Here’s a breakdown of its working principle:

- Material Feeding: The wet material, often in the form of a paste, cake, or slurry, is fed into the dryer system. It’s typically pre-conditioned or disintegrated to ensure it’s in a fine, dispersible form.

- Hot Air Generation: A hot air generator or furnace produces a stream of hot drying gas (usually air, but sometimes inert gas for sensitive materials).

- Mixing and Drying Chamber: The hot gas is introduced into the drying chamber at high velocity. The wet material is then injected into this high-velocity hot gas stream. This creates a turbulent environment where the material is rapidly dispersed and intimately mixed with the hot gas.

- Instantaneous Evaporation (Flash Drying): Due to the high temperature of the gas and the large surface area created by the dispersed particles, moisture rapidly evaporates from the material. The residence time of the material in the drying chamber is very short, often just a few seconds, hence the term “flash” drying.

- Particle Separation: After drying, the mixture of dry product and spent gas moves to a separation system, typically a cyclone separator. The centrifugal force in the cyclone separates the dried solid particles from the gas stream.

- Product Collection: The dried product is collected at the bottom of the cyclone or through other collection devices like bag filters.

- Exhaust Gas Treatment: The spent gas, now cooler and laden with evaporated moisture, is often vented to the atmosphere after passing through dust collection systems (like bag filters or scrubbers) to meet environmental regulations.

This process is highly efficient for materials that can be easily dispersed and require rapid drying, minimizing degradation and maintaining product quality.