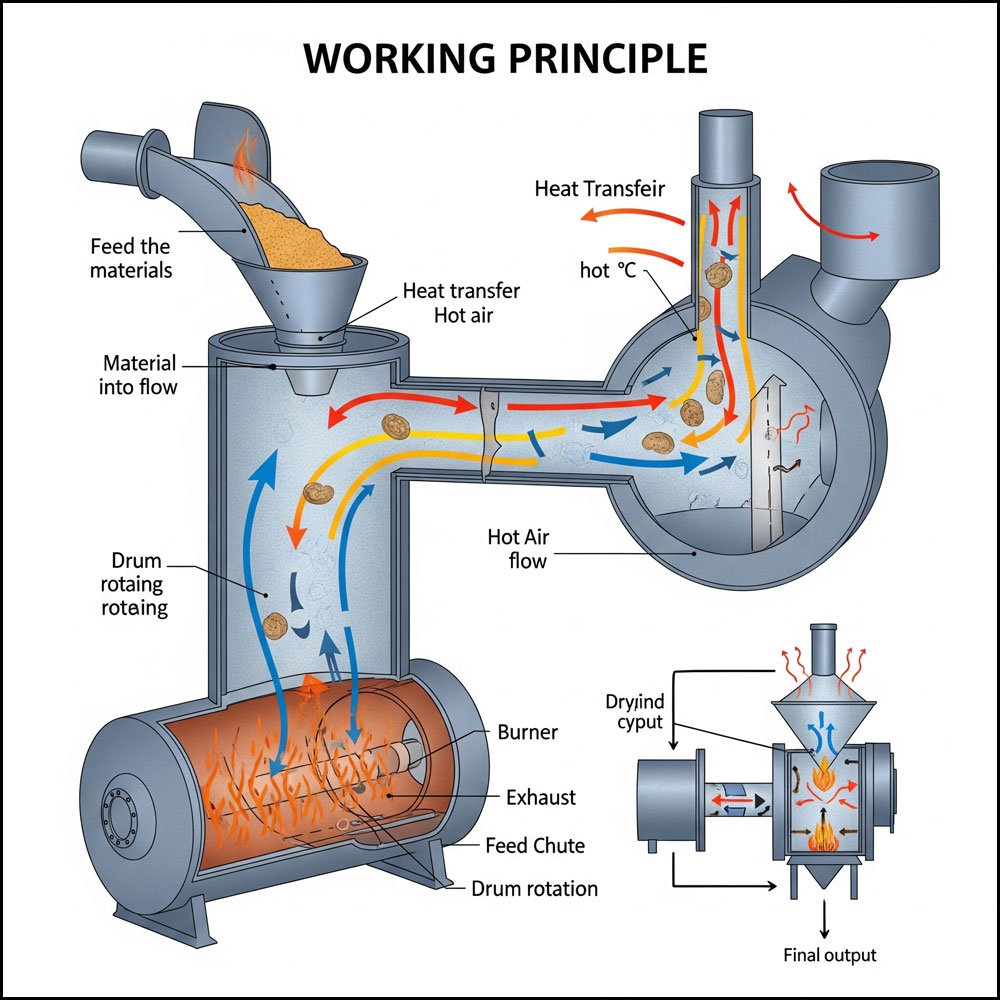

A rotary dryer, also known as a rotary drum dryer, is an industrial drying machine used to reduce the moisture content of various bulk materials. Its working principle relies on a combination of heat transfer, mechanical action, and gravity to efficiently dry the material.

Here’s a breakdown of the rotary dryer’s working principle:

1. Basic Components:

- Rotating Cylinder (Drum/Shell): This is the core of the dryer, a large, slightly inclined cylindrical tube made of steel that rotates on its axis.

- Drive Mechanism: A motor and gear system that rotates the drum at a controlled speed.

- Support Structure: Typically concrete posts or a steel frame that supports the rotating drum.

- Internal Flights (Lifting Flights/Lifters): These are metal fins or baffles lining the inner wall of the drum.

- Heat Source: A burner (gas, oil, coal) or heat exchanger that generates hot air or gas.

- Feed and Discharge Systems: For introducing wet material and collecting dried material.

- Exhaust System: To remove moisture-laden air and sometimes include dust collectors.

2. The Drying Process:

- Material Feed: Wet material is continuously fed into the higher end of the slightly inclined rotating drum.

- Drum Rotation and Material Movement: As the drum rotates, the material is slowly conveyed from the higher feed end to the lower discharge end due to gravity and the rotational movement.

- Lifting and Cascading Action: The internal flights play a crucial role. As the drum rotates, these flights scoop up the wet material, lifting it upwards. When the material reaches a certain height, it tumbles and cascades back down through the hot gas stream. This continuous lifting and falling action maximizes the surface area exposure of the material to the heated air.

- Heat Transfer:

- Direct Heating: In most common rotary dryers, hot air or combustion gases are directly introduced into the drum. This hot gas comes into direct contact with the cascading material, transferring heat to it by convection. The heat causes the moisture in the material to evaporate.

- Indirect Heating: For heat-sensitive materials or when product contamination by combustion gases is a concern, indirect heating is used. Here, the drum is externally heated (e.g., by a jacket with steam or hot oil), or internal tubes carry the heating medium. Heat is transferred to the material primarily by conduction through the drum walls or heating tubes.

- Airflow Direction (Direct Heating):

- Co-current flow (Parallel Flow): Hot gas flows in the same direction as the material (from feed end to discharge end). This results in rapid initial evaporation and a quicker cooling of the hot gas, which can be beneficial for high-moisture, sticky materials.

- Counter-current flow: Hot gas flows in the opposite direction to the material (from discharge end to feed end). This is often preferred for materials requiring very low final moisture content and uniform drying, as the driest material comes into contact with the hottest gas.

- Moisture Removal: As the material tumbles through the hot air, moisture evaporates and is carried away by the exhaust system. Filters or dust collectors are often used in the exhaust system to capture any fine particles before releasing the air.

- Discharge: Once the material reaches the desired moisture content, it exits the dryer from the lower discharge end.

Key Principles at Play:

- Convection: The primary mode of heat transfer in direct rotary dryers, where heat is transferred from the hot gas to the material through fluid movement.

- Conduction: Heat transfer through direct contact between the heated drum/flights and the material, more prominent in indirect dryers.

- Evaporation: The phase change of water from liquid to vapor, driven by the heat supplied.

- Gravity: Facilitates the movement of material through the inclined drum.

- Mechanical Agitation: The rotation of the drum and the action of the flights ensure uniform exposure of the material to heat and prevent clumping, leading to efficient and consistent drying.

The design and operation parameters of a rotary dryer, such as drum inclination, rotation speed, flight design, and heat source, can be adjusted to optimize the drying process for different types of materials and desired final moisture content.