As the food industry increasingly focuses on environmental responsibility and operational efficiency, sustainable spray drying practices are becoming not just desirable but essential. Spray drying is energy-intensive, so optimizing its sustainability has a significant impact.

Here’s an overview of sustainable spray drying practices for the food industry:

Sustainable Spray Drying Practices for the Food Industry

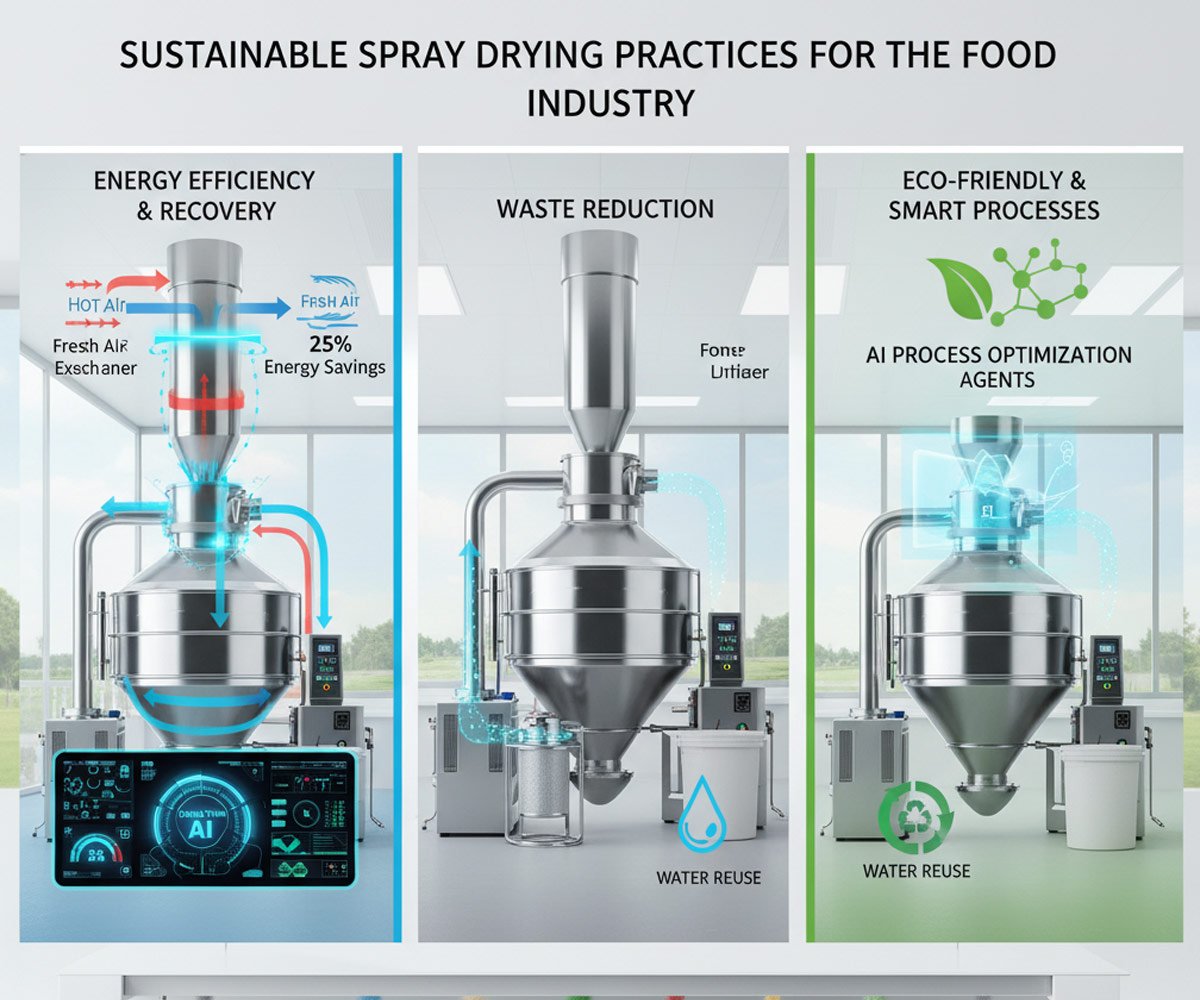

Sustainable spray drying focuses on reducing energy consumption, minimizing waste, and employing eco-friendly materials and processes throughout the operation.

1. Energy Efficiency and Recovery

- Heat Recovery Systems: This is arguably the most impactful area. Exhaust air from the spray dryer (still hot) can be passed through heat exchangers to pre-heat the incoming fresh air. This can significantly reduce the energy required to heat the drying air, leading to 20-30% or even higher energy savings.

- Optimal Process Control (Digital Twin/AI):

- Precise Temperature & Airflow Management: Advanced control systems, often leveraging Digital Twins and AI/ML algorithms, continuously monitor and adjust drying parameters (inlet/outlet temperatures, airflow rates, feed concentration) in real-time. This ensures the dryer operates at its most energy-efficient point while maintaining product quality.

- Reduced Over-Drying: Preventing over-drying saves energy, as evaporating the last bit of moisture is the most energy-intensive.

- Feed Concentration: Concentrating the liquid feed (e.g., via evaporation, reverse osmosis, or ultrafiltration) before it enters the spray dryer reduces the amount of water that needs to be evaporated in the dryer itself, thereby significantly lowering energy demand.

- Efficient Atomization: Utilizing modern, optimized atomizers (rotary or nozzle) that produce a highly uniform droplet size distribution. This ensures efficient drying and prevents the need for excessive heat or airflow.

2. Waste Reduction and Resource Optimization

- High Yield Dryer Design: Implementing advanced cyclone and filter designs (e.g., bag filters) to maximize powder recovery and minimize product loss (dust) into the exhaust air.

- Water Recycling & Reuse: In systems where water is condensed from the exhaust air or used for cleaning, advanced filtration and purification systems can enable its reuse, particularly for non-contact applications or as part of the feed preparation.

- Minimizing Cleaning-in-Place (CIP) Waste: Optimizing CIP cycles to use less water, chemicals, and energy, without compromising hygiene standards.

- Smart Raw Material Sourcing: Utilizing co-products or by-products from other food processes as feed materials (e.g., whey from cheese production, fruit pomace extracts) or as sustainable carrier agents, thereby reducing waste from other streams.

3. Eco-Friendly Materials and Formulations

- Sustainable Carrier Agents: Prioritizing carrier agents (like maltodextrin, gum arabic) that are sustainably sourced, biodegradable, and produced with minimal environmental impact. Research into novel, naturally derived encapsulating agents is ongoing.

- Reduced Additive Use: Optimizing formulations and drying parameters to minimize the need for synthetic anti-caking agents or other processing aids.

- Biodegradable Packaging: While not directly a spray drying practice, ensuring the output powder is packaged in sustainable, recyclable, or biodegradable materials aligns with overall sustainability goals.

4. Process Intensification and Advanced Technologies

- Hybrid Drying Technologies: Exploring combinations of drying methods (e.g., spray drying followed by fluidized bed drying) that can offer improved energy efficiency and product quality for specific applications.

- Closed-Loop Systems: For certain applications involving organic solvents (e.g., flavor extraction, certain nutraceuticals), using closed-loop systems with inert gases or solvent recovery can drastically reduce emissions and enhance safety.

By implementing these sustainable practices, the food industry can transform spray drying from an energy-intensive process into an environmentally conscious operation, contributing to both ecological well-being and long-term economic viability.