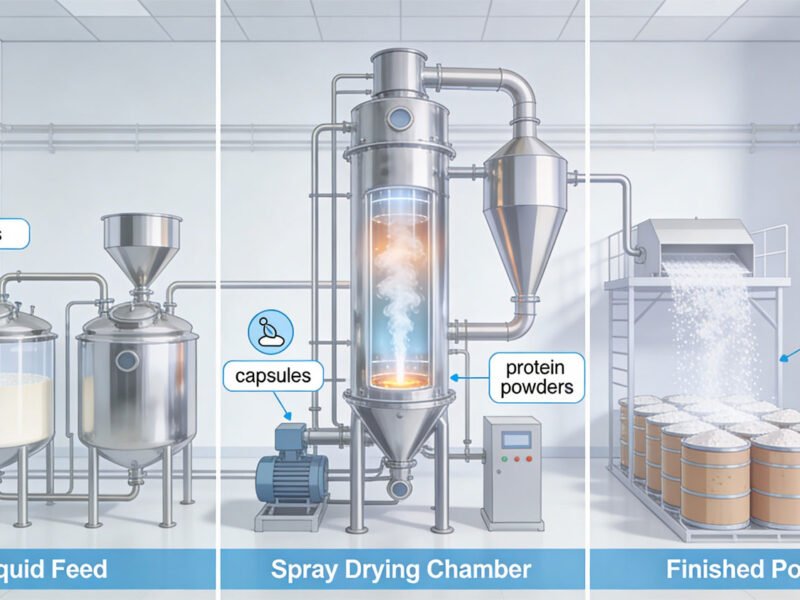

A spray dryer is an industrial process used to transform a liquid feed (solution, slurry, emulsion, or suspension) into a dry powder or granular form in a single, continuous step. This method is particularly favored for heat-sensitive materials because of its rapid drying time.

Here’s a breakdown of the spray dryer working principle, typically involving three main stages:

1. Feed Preparation: The liquid to be dried is prepared to ensure it’s suitable for the atomization process. This might involve:

- Concentration: Increasing the solid content to reduce the amount of liquid that needs to be evaporated, improving efficiency.

- Homogenization: Ensuring a uniform mixture of components.

- Adjusting Viscosity: Optimizing the liquid’s flow properties for effective atomization.

- Filtering: Removing impurities that could clog the atomizer.

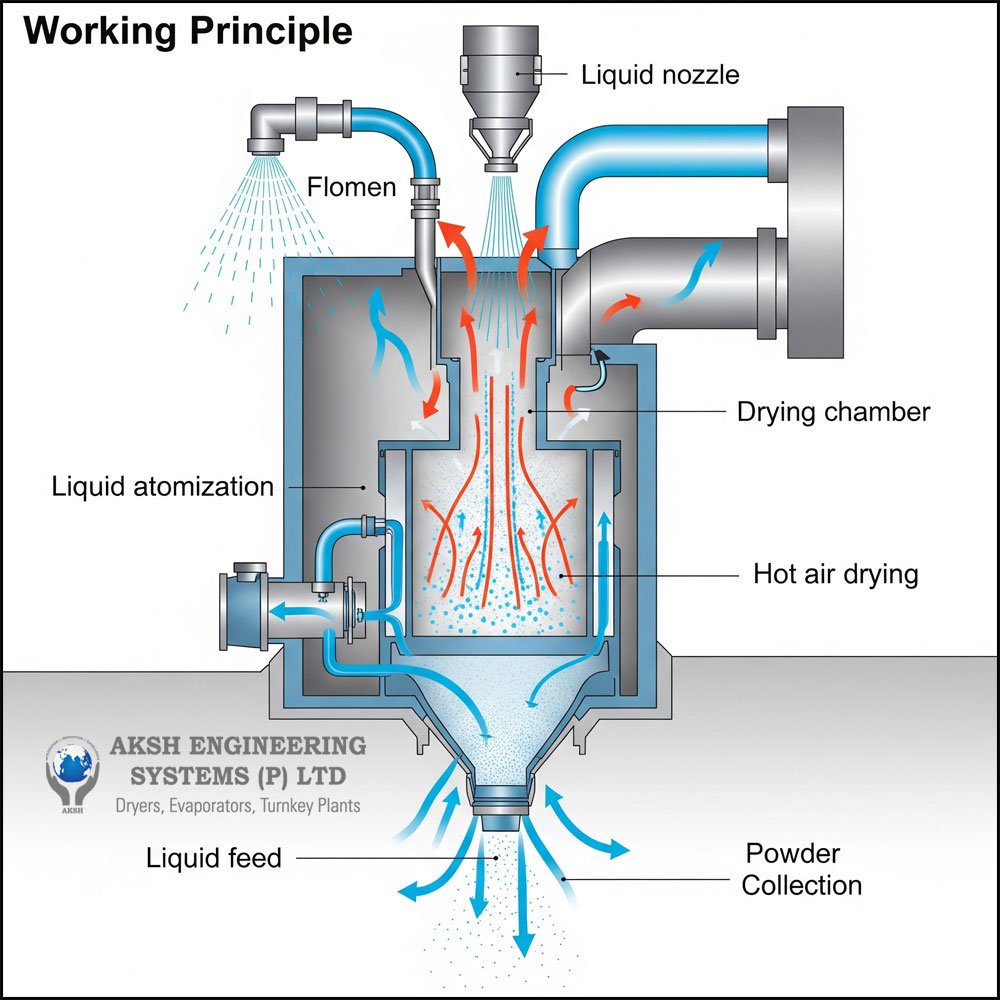

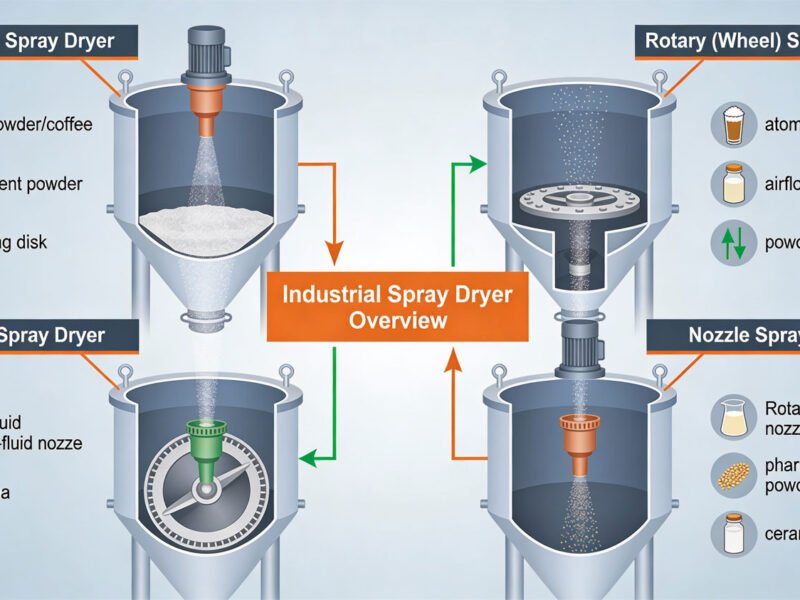

2. Atomization: This is the crucial step where the liquid feed is transformed into a fine mist of tiny droplets. This dramatically increases the surface area of the liquid, facilitating rapid heat and mass transfer. Common atomization methods include:

- Nozzle Atomizers:

- Pressure Nozzles: A high-pressure pump forces the liquid through a small orifice, creating a fine spray. This often produces a consistent and narrow particle size distribution.

- Two-fluid Nozzles: Compressed gas (like air or steam) is used to break up the liquid into fine droplets.

- Rotary Atomizers (Spinning Disk Atomizers): The liquid is fed onto a rapidly rotating disk, and centrifugal force throws the liquid off the disk’s edge, atomizing it into droplets. This method can be energy-efficient and offer a narrow particle size distribution.

3. Drying in the Chamber (Evaporation): The fine droplets are then introduced into a large drying chamber, where they come into contact with a stream of hot gas (most commonly hot air, but nitrogen is used for flammable solvents or oxygen-sensitive products).

- Heat Transfer: The hot gas rapidly transfers heat to the surface of the tiny liquid droplets.

- Moisture Evaporation: Due to the large surface area and high temperature, the moisture in the droplets evaporates almost instantly, typically within a few seconds.

- Particle Formation: As the solvent evaporates, the solid content within each droplet forms a dry particle. The temperature and flow rate of the hot air are carefully controlled to achieve the desired particle size, morphology (shape), and residual moisture content.

- Flow Patterns: The hot air and spray can be introduced in different flow patterns (co-current, counter-current, or mixed) which influence the drying characteristics and product properties. In co-current flow, both the spray and hot air move in the same direction, which is often preferred for heat-sensitive materials as the hottest air contacts the wettest particles, preventing overheating.

4. Particle Separation and Collection: Once dried, the solid particles need to be separated from the moist exhaust gas.

- Primary Collection: The larger, heavier dried particles typically fall to the bottom of the drying chamber and are collected.

- Fines Recovery: A portion of finer particles may remain entrained in the exhaust air. These are usually recovered using:

- Cyclone Separators: These use centrifugal force to separate the particles from the gas stream. The gas enters tangentially, creating a vortex, and the heavier particles are thrown to the outer wall and collected at the bottom.

- Bag Filters: These capture fine particles on the surface of fabric bags.

- Exhaust Gas Treatment: The exhaust air, now containing evaporated moisture, is often filtered before being released to the atmosphere, ensuring environmental compliance. In some closed-cycle systems, the drying medium (e.g., nitrogen) is recovered and recirculated.

Key Advantages of Spray Drying:

- Rapid Drying: Due to the large surface area of the droplets, drying occurs very quickly, minimizing exposure of the product to high temperatures. This is ideal for heat-sensitive materials.

- Continuous Process: Allows for high production rates.

- Flexible Control over Product Properties: Parameters like inlet and outlet temperatures, feed rate, and atomizer type can be adjusted to control particle size, density, shape, and moisture content.

- Single-Step Process: Converts liquid directly to dry powder, eliminating intermediate steps like filtration or grinding.

- Versatility: Can be used for a wide range of materials in various industries (food, pharmaceutical, chemical, etc.).