A pilot spray dryer is a smaller-scale version of industrial spray dryers, designed specifically for research, development, and small-batch production. It allows companies and researchers to test and optimize spray drying processes on a manageable scale before committing to full-scale commercial manufacturing.

What Is a Pilot Spray Dryer?

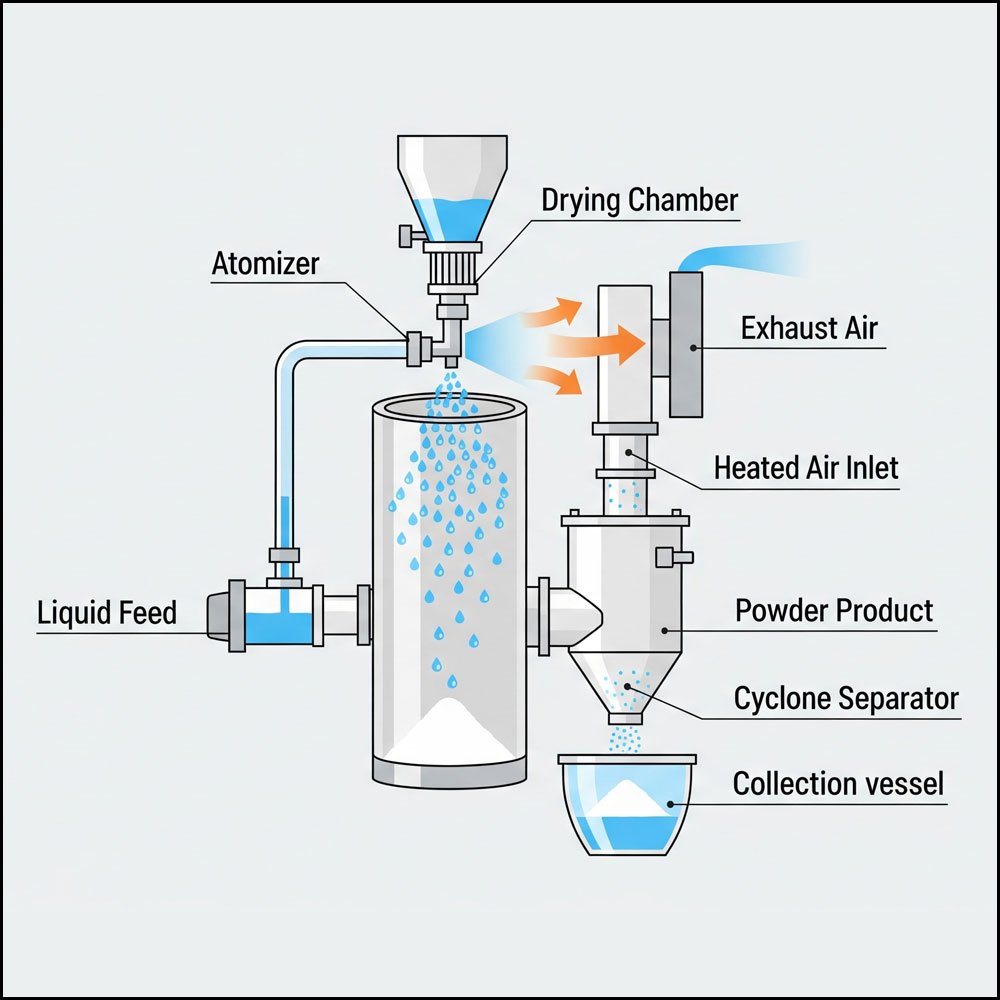

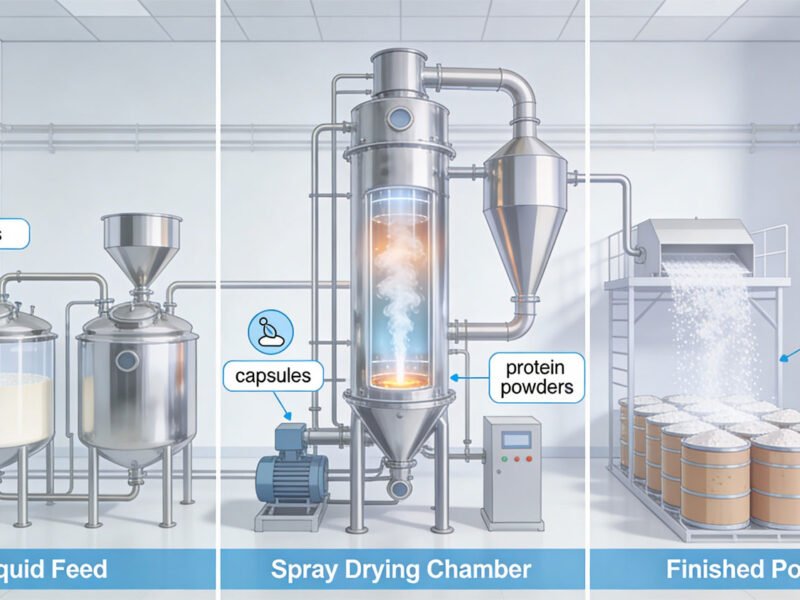

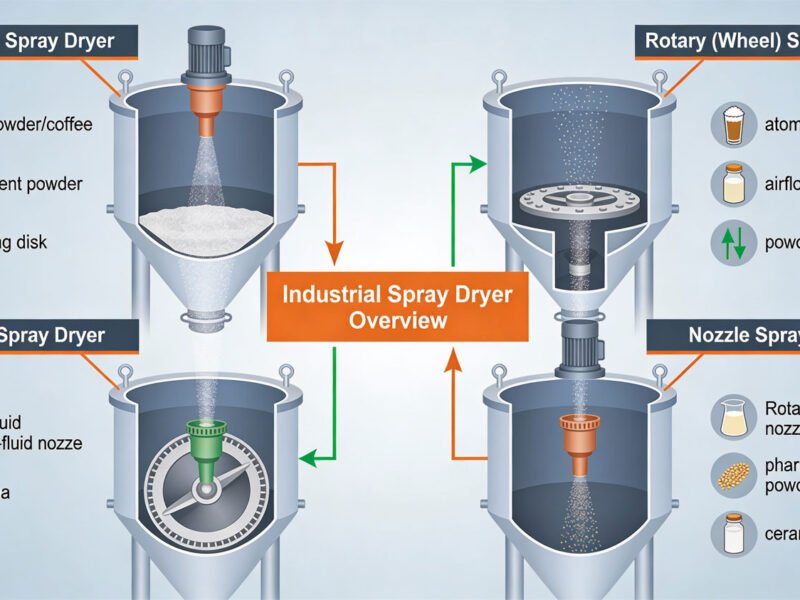

A pilot spray dryer operates on the same fundamental principles as a large industrial spray dryer—it atomizes a liquid feed into fine droplets and exposes them to hot air to rapidly evaporate moisture, producing dry powder. However, pilot units handle much smaller volumes (typically from a few milliliters to several liters per hour), making them ideal for product development and process optimization.

Why Pilot Spray Dryers Matter in Product Development

- Process Optimization

Pilot spray dryers enable precise control over drying parameters such as inlet temperature, feed rate, and atomization, allowing developers to fine-tune product characteristics like particle size, moisture content, and solubility. - Cost and Material Efficiency

Working on a small scale reduces the consumption of costly raw materials during formulation trials, making it an economical choice for R&D teams. - Scale-Up Data Collection

They provide critical data about how the formulation behaves during drying, which helps in designing and scaling up to industrial production. Variables such as drying time, airflow, and powder yield can be measured and adjusted. - Versatility Across Industries

Pilot spray dryers are used in pharmaceuticals, food, cosmetics, and chemicals to develop new powders, encapsulate active ingredients, and create stable, uniform products. - Safe Testing of Sensitive Products

The controlled environment of pilot units facilitates drying of heat-sensitive or reactive materials with minimal risk, preserving product quality.

In summary, pilot spray dryers are essential tools in product development that bridge the gap between lab research and commercial production. They offer a controlled, flexible, and cost-effective platform to optimize drying processes, ensuring successful product launch and manufacturing efficiency.