Choosing the right spray drying technology is not just a matter of mechanical preference; it is a critical strategic decision that dictates the quality, solubility, and cost-efficiency of your final product. At AKSH Engineering Systems Pvt Ltd, we understand that every liquid feed—whether a delicate pharmaceutical protein or a rugged chemical slurry—requires a specific atomization strategy to achieve the perfect powder.

In this comprehensive guide, we explore the primary types of industrial spray dryers, their mechanical principles, and the specific industries where they excel.

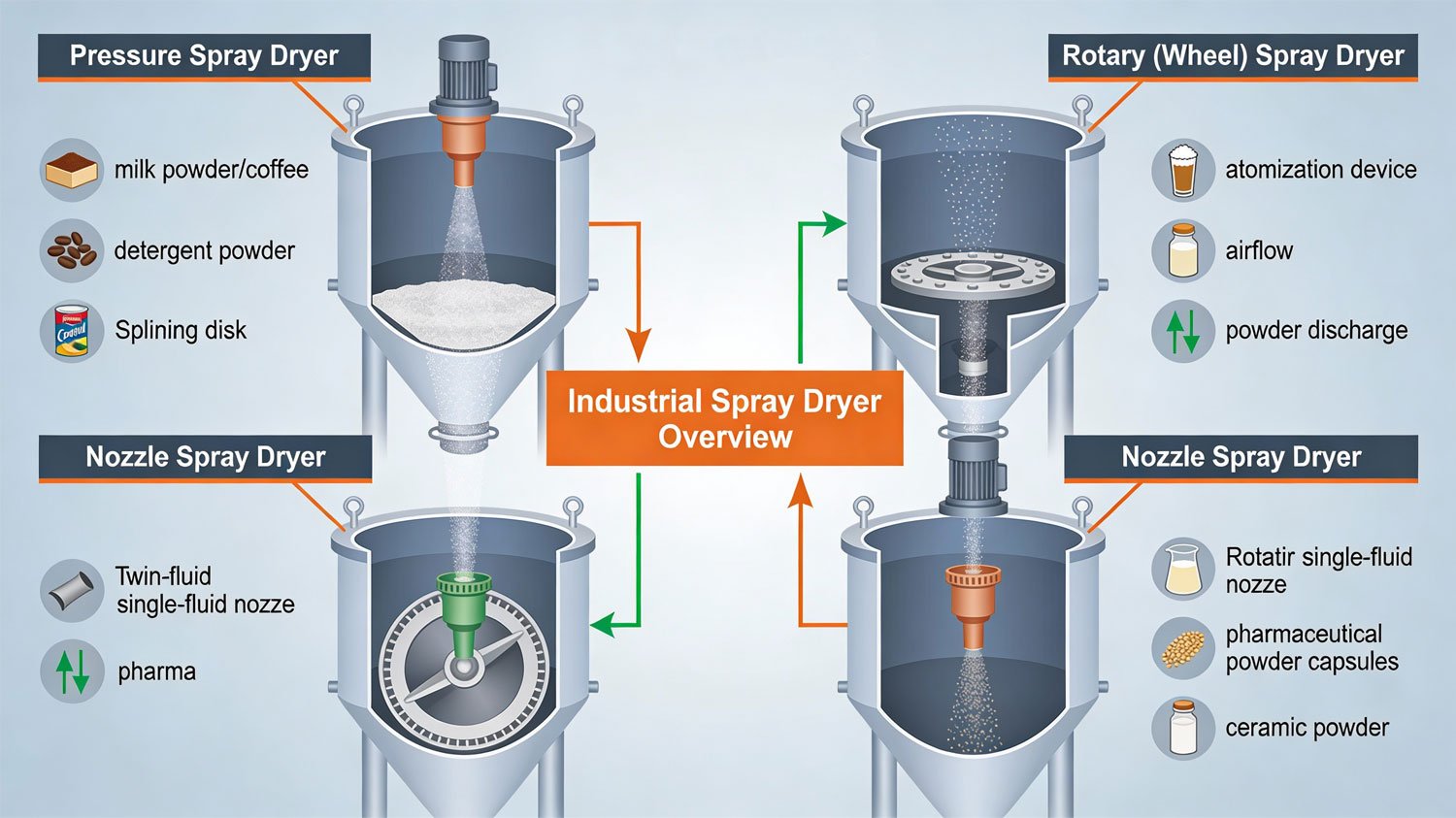

1. Rotary Atomizer Spray Dryers (Centrifugal Type)

The rotary atomizer is often considered the “workhorse” of large-scale industrial production. Instead of using high-pressure pumps to force liquid through a hole, it uses centrifugal force to fling the liquid outward.

Working Principle

Liquid feed is introduced onto the center of a high-speed rotating disk or wheel (spinning between 10,000 to 30,000 RPM). As the disk spins, the liquid is accelerated to the periphery, where it is sheared into a fine mist of droplets by the high velocity.

Key Features of AKSH Rotary Systems:

- High Versatility: Excellent at handling abrasive slurries or feeds with high solid content that would typically clog a nozzle.

- Flexibility: Droplet size can be adjusted simply by changing the disk speed via a Variable Frequency Drive (VFD).

- Durability: Since it operates at lower liquid pressures, there is significantly less wear and tear on the pumping system.

Ideal Applications:

- Dairy Industry: Large-scale production of milk and whey powder.

- Chemicals: Detergents, dyes, and pigments.

- Ceramics: Preparing fine ceramic powders for high-tech manufacturing.

- Effluent Treatment: Used in Zero Liquid Discharge (ZLD) plants for high-volume wastewater evaporation.

2. Pressure Nozzle Spray Dryers (Single-Fluid)

When your product requires a very specific, coarse, and uniform particle size, the Pressure Nozzle system is the preferred choice.

Working Principle

The liquid feed is pressurized using a high-pressure pump (often up to 250–350 bar) and forced through a small, precision-engineered orifice. The sudden drop in pressure as the liquid exits the nozzle causes it to “explode” into a hollow-cone spray pattern.

Why Choose a Pressure Nozzle?

- Narrow Particle Size Distribution: It produces highly uniform granules with excellent flowability.

- Lower Air Velocity: Typically results in a more compact powder with higher bulk density.

- Energy Efficiency: For low-viscosity liquids, pressure atomization often consumes less energy than rotary systems.

Ideal Applications:

- Food & Beverage: Instant coffee, tea extracts, and egg powder.

- Pharmaceuticals: Producing granules for direct compression into tablets.

- Fragrances: Encapsulating flavors and aromas to protect volatile oils.

3. Two-Fluid Nozzle Spray Dryers (Pneumatic)

For Research & Development or the production of extremely fine, specialized powders, the Two-Fluid Nozzle offers unmatched control.

Working Principle

This system uses two separate streams: the liquid feed and a compressed gas (usually air or nitrogen). The gas meets the liquid either inside the nozzle (internal mix) or just as it exits (external mix). The high-velocity gas shears the liquid into ultra-fine droplets.

Advantages:

- Micro-Fine Particles: Capable of producing particles smaller than 50 microns.

- Viscosity Handling: Can handle viscous feeds that are too thick for standard pressure nozzles but required in smaller volumes than a rotary system.

- Cooler Operation: The expansion of the compressed air can provide a slight cooling effect, beneficial for extremely heat-sensitive biologicals.

Ideal Applications:

- Pilot Plants: Perfect for R&D labs and small-batch specialty chemicals.

- Biotechnology: Drying enzymes, vaccines, and microbial cultures.

- Advanced Materials: Nanoparticles and specialized catalysts.

4. Multi-Stage and Integrated Fluid Bed Dryers

Modern industrial requirements often go beyond a single drying step. AKSH Engineering specializes in Integrated Multi-Stage systems that combine a spray dryer with a fluid bed at the bottom of the chamber.

How it Works:

- Stage 1: Initial spray drying in the main chamber.

- Stage 2: The semi-dry powder falls onto an integrated fluid bed where it undergoes gentle secondary drying.

- Agglomeration: The moist particles collide in the fluid bed, “sticking” together to form larger, dust-free agglomerates.

Benefits:

- Instant Solubility: Produces “instantized” powders that dissolve immediately in water.

- Dust-Free: Removes fine particles that cause dust clouds during packaging.

- Energy Savings: Allows for lower exhaust temperatures, increasing overall thermal efficiency.

Comparative Summary: Choosing the Right Dryer

| Feature | Rotary Atomizer | Pressure Nozzle | Two-Fluid Nozzle |

| Particle Size | Fine to Medium | Coarse/Uniform | Very Fine |

| Capacity | High (Up to 15T/hr) | Medium | Low to Medium |

| Viscosity Handling | Excellent | Limited | Good |

| Maintenance | High (Mechanical) | Medium (Nozzle Wear) | Low |

| Primary Goal | High Throughput | Uniform Granules | Fine/Specialty Powder |

Conclusion: Engineering the Perfect Particle

Selecting between rotary, pressure, or nozzle atomization depends entirely on your product’s “personality”—its viscosity, heat sensitivity, and desired final flowability.

At AKSH Engineering Systems Pvt Ltd, we don’t just manufacture machines; we engineer processes. Our pilot plant facilities allow you to test your material across different atomization methods to determine the most cost-effective and high-quality path forward.