A laboratory spray dryer is a critical piece of equipment for R&D, pilot work, and small-scale production, especially for heat-sensitive food products. Achieving optimum efficiency (high yield, consistent quality) and maintaining the equipment properly are essential for reliable experimental results.

Here are detailed tips for both optimizing efficiency and maintaining your lab-scale spray dryer:

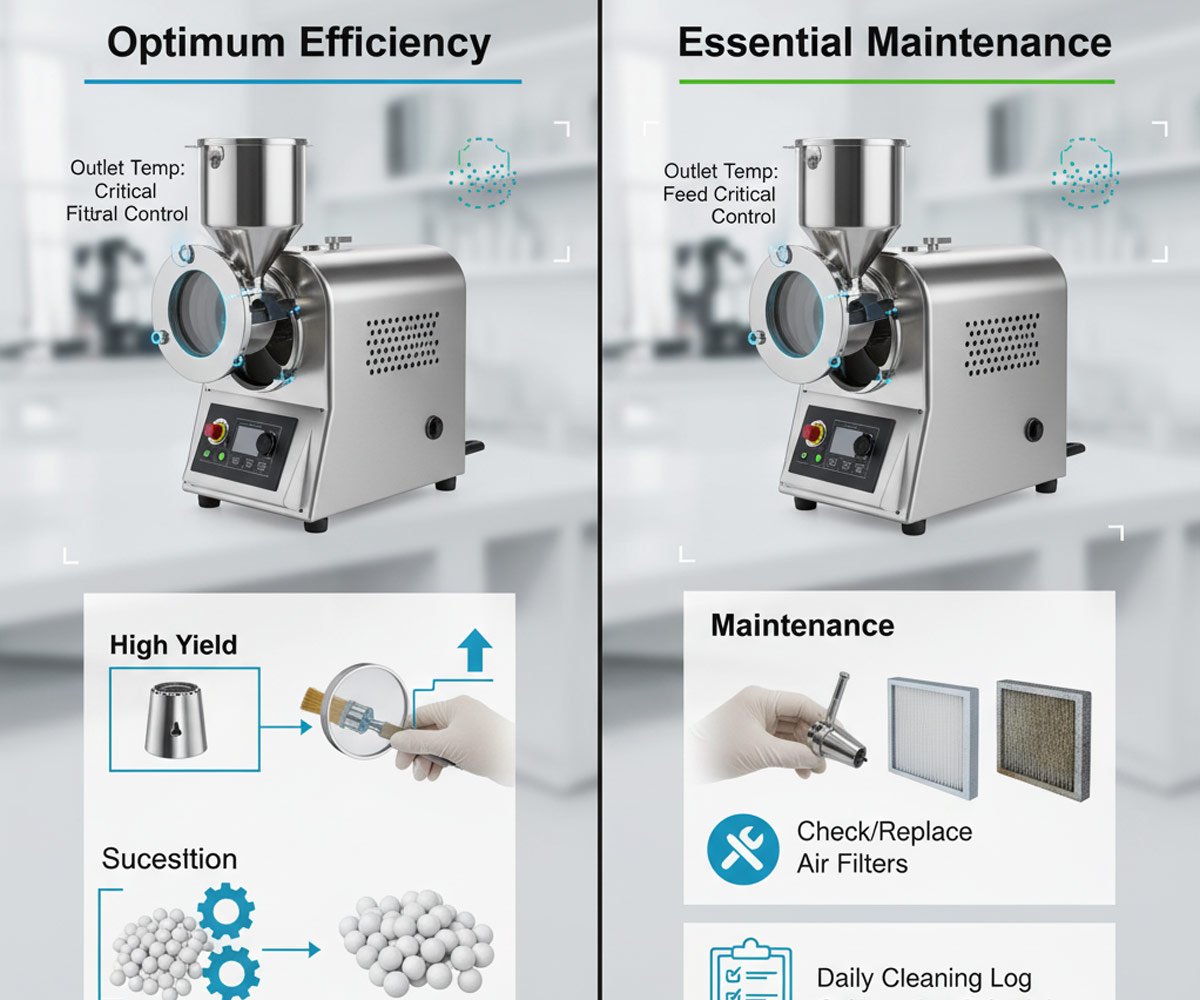

Tips for Optimum Efficiency and High Yield

Efficiency in a lab spray dryer is primarily defined by the powder yield and the reproducibility of results.

1. Feed Preparation & Optimization

- Maximize Solids Content: The lower the water content in your liquid feed, the less energy is required for evaporation and the higher the process throughput. Concentrate the feed solution to the maximum pumpable viscosity before drying.

- Use Carrier Agents: For sticky or highly hygroscopic materials (like high-sugar fruit extracts), always incorporate drying aids (e.g., maltodextrin, gum arabic). This prevents wall deposition and drastically increases powder yield.

- Pre-Filter the Feed: Always filter the liquid feed before introduction to the pump/nozzle to prevent blockages, which are a major cause of downtime and inconsistent spray patterns.

- Pre-Heat the Feed: If the material allows, pre-heating the feed slightly reduces the energy needed from the hot air for evaporation, improving efficiency.

2. Process Parameter Control

- Control Outlet Temperature: This is the most critical control point. Set the to be slightly above the final desired product temperature and, crucially, below the product’s Glass Transition Temperature plus a buffer. This prevents product stickiness and wall fouling.

- Tip: The is controlled by adjusting the Feed Rate and Inlet Temperature.

- Optimize Atomization:

- Adjust the atomization pressure (for 2-fluid nozzles) or speed (for rotary atomizers) to achieve the ideal droplet size. Finer droplets dry faster but can lead to more loss in the exhaust air.

- Ensure the atomizer is concentric and the spray pattern is stable and uniform.

- Airflow Management: Operate the dryer with the highest safe airflow rate. Higher airflow rates reduce the residence time of particles on the chamber walls, improving yield.

3. Smart Operation

- Run-Time Optimization: Stabilize the dryer with pure water or solvent before introducing the product feed. This allows the temperatures and flow rates to reach steady state, preventing initial loss of product.

- Design of Experiments (DoE): Utilize DoE methodologies to systematically find the optimal combination and feed rate for your specific formulation, rather than relying on trial-and-error.

Essential Maintenance and Reliability

Consistent and accurate experimental work relies on a well-maintained machine. Implement a strict maintenance schedule.

1. Daily/Per-Use Cleaning and Inspection

- Nozzle and Atomizer: This is the most sensitive part.

- Immediately after use, flush the feed line and nozzle/atomizer assembly with the feed solvent (e.g., water) until completely clean.

- Periodically disassemble and visually inspect the nozzle components (orifice and cap) for wear, erosion, or blockage. Even minor wear can drastically change the spray pattern and particle size.

- Feed System: Inspect all peristaltic pump tubing, check valves, and fittings for signs of wear, leaks, or product build-up. Replace tubing regularly as per the manufacturer’s recommendation.

- Collection Vessels: Ensure the cyclone and collection vessel seals are intact to prevent air leaks, which compromise the vacuum and reduce powder collection efficiency.

2. Scheduled Maintenance (Weekly/Monthly)

- Air Filters: Check and clean or replace inlet and outlet air filters regularly. Clogged filters reduce airflow, decrease efficiency, and can strain the fan/blower motor.

- Heating System Check: Verify that the electric heaters (or gas burner, if applicable) are functioning correctly and that the heat shield/insulation is undamaged to ensure thermal efficiency.

- Blower/Fan Inspection: Listen for unusual noises or vibrations, which can indicate bearing wear or imbalance. Ensure all lubrication points (if applicable) are maintained according to the manual.

3. Calibration and Documentation

- Sensor Calibration: Regularly calibrate all critical sensors, especially the temperature probes, to ensure accuracy and reproducibility between batches.

- Maintenance Log: Document everything. Maintain a detailed log of all runs, parameter settings, maintenance tasks performed, and any parts replaced. This data is invaluable for troubleshooting sudden performance issues.

- Troubleshooting Guide: Keep the manufacturer’s troubleshooting guide easily accessible. Most issues (low yield, wet powder, wall sticking) are solved by adjusting one of the three main variables: Feed Rate, Inlet Temperature, or Airflow.