Spray dryers are incredibly versatile and find widespread use across numerous industries for converting liquid feedstocks into dry powders. Here’s a breakdown of their key applications across different sectors:

Food Industry: This is one of the largest users of spray drying technology. Applications include:

- Dairy Products: Milk powder, whey powder, caseinates, infant formula. Spray drying extends shelf life, reduces volume for transport, and creates easily soluble powders.

- Beverages: Instant coffee and tea, malt extracts, powdered juices, drink mixes, flavorings, and colorings.

- Eggs: Egg powder (whole egg, egg yolk, egg white) for baking and food processing.

- Fruits and Vegetables: Production of fruit and vegetable powders for instant products, flavorings, and nutritional supplements.

- Starches and Sweeteners: Drying of starch derivatives, glucose syrups, dextrose, and other sweeteners.

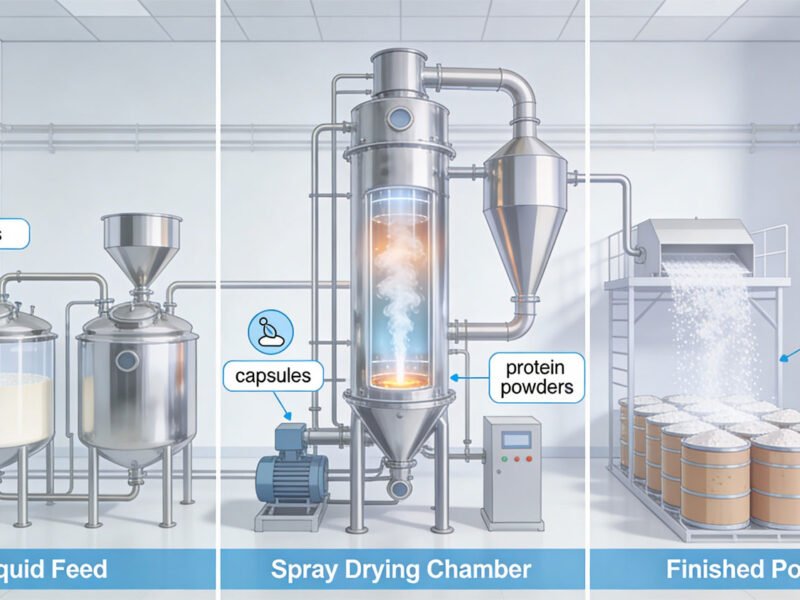

- Proteins: Production of plant-based and animal-based protein powders.

- Encapsulation: Encapsulating flavors, oils, vitamins, and other food ingredients to protect them, control release, or improve handling.

- Soups and Sauces: Manufacturing powdered soup mixes, sauce powders, and gravy powders.

- Animal Feed: Production of powdered feed ingredients.

Pharmaceutical Industry: Spray drying is crucial for producing various pharmaceutical products:

- Active Pharmaceutical Ingredients (APIs): Creating fine powders of drugs for tablets, capsules, and other solid dosage forms, often to improve bioavailability and dissolution rates.

- Amorphous Solid Dispersions (ASDs): Enhancing the solubility of poorly water-soluble drugs by dispersing them in a polymer matrix.

- Inhalable Powders: Producing micron-sized drug particles for pulmonary drug delivery.

- Granulation: Creating granules with improved flowability and compressibility for tablet manufacturing.

- Encapsulation: Coating drug particles for controlled release, taste masking, or protection from degradation.

- Biopharmaceuticals: Drying of sensitive biological materials like proteins, enzymes, vaccines, and antibodies.

- Excipients: Processing pharmaceutical excipients like lactose, cellulose derivatives, and starches.

Chemical Industry: Spray drying is used to produce a wide range of chemical products:

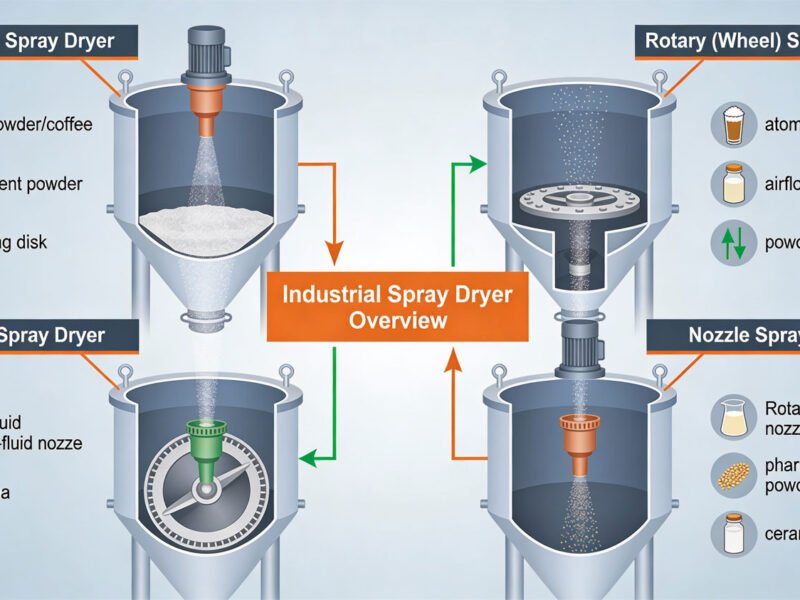

- Catalysts: Manufacturing catalysts with controlled particle size and morphology for various chemical reactions.

- Pigments and Dyes: Producing fine and uniform pigment and dye powders for paints, inks, and coatings.

- Detergents and Soaps: Creating powdered detergents and soaps with specific particle properties for optimal performance.

- Polymers and Resins: Drying polymer solutions and emulsions to produce powdered resins for various applications.

- Ceramics: Manufacturing fine ceramic powders for advanced materials and industrial applications.

- Agrochemicals: Producing powdered pesticides, herbicides, fungicides, and fertilizers.

- Inorganic Chemicals: Drying solutions of various inorganic salts and compounds.

- Battery Materials: Processing materials for lithium-ion batteries and other energy storage devices.

Materials Science: Spray drying plays a role in the synthesis of advanced materials:

- Nanoparticles: Controlled production of nanoparticles with specific size and morphology.

- Coatings: Creating precursor powders for various coating technologies.

- Advanced Ceramics: Manufacturing specialized ceramic powders for electronics, aerospace, and other high-tech applications.

- Powder Metallurgy: Producing metal powders with controlled characteristics for additive manufacturing and powder metallurgy processes.

Other Industries:

- Biotechnology: Drying of microorganisms, enzymes, and other biological products.

- Environmental: Processing wastewater treatment sludges and other waste materials into dry solids.

- Cosmetics: Production of cosmetic powders, pigments, and encapsulated ingredients for personal care products (sometimes using spray cooling for fats and waxes).

- Agriculture: Production of animal feed supplements and other agricultural products.

In summary, spray drying is a fundamental process for transforming liquids into powders across a vast spectrum of industries due to its speed, efficiency, ability to handle heat-sensitive materials, and capacity to produce powders with controlled properties.