Selecting the optimal spray drying system is one of the most critical capital investment decisions a chemical manufacturer can make. When dealing with chemical slurries—which often involve complex rheology, heat sensitivity, and abrasive or corrosive properties—the stakes are even higher.

At AKSH Engineering Systems Pvt. Ltd., we believe that a spray dryer is not just a piece of equipment; it is a precision instrument designed to transform liquid feed into high-value solid particles. This guide outlines the technical considerations, engineering nuances, and selection criteria for choosing the right system for your facility.

1. Understanding the Fundamental Process

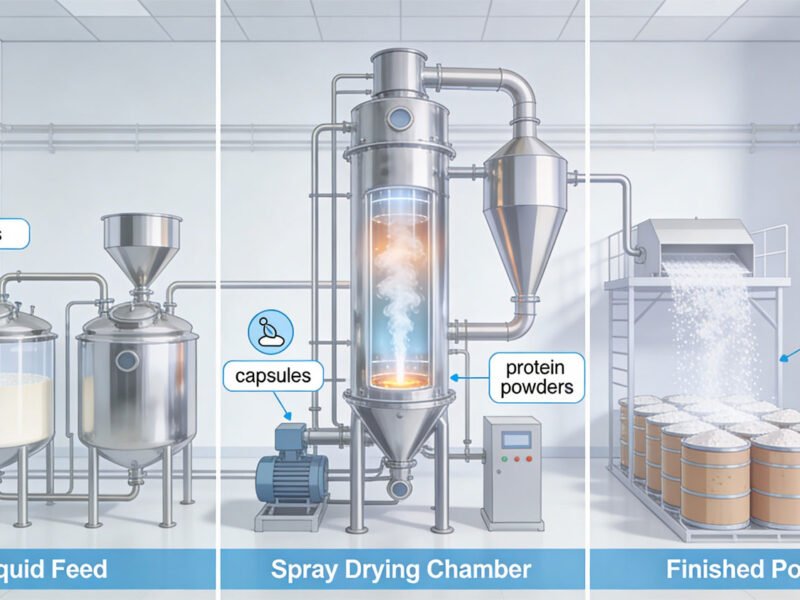

Spray drying is the continuous transformation of a feed from a fluid state (slurry, suspension, or emulsion) into a dried particulate form by spraying the feed into a hot drying medium.

The Four Stages of Spray Drying:

- Atomization: Converting the slurry into a cloud of fine droplets.

- Spray-Air Contact: Mixing the droplets with hot drying gas.

- Drying: Moisture evaporation as droplets travel through the chamber.

- Separation: Recovering the dried powder from the gas stream.

2. Analyzing Your Slurry Characteristics

Before looking at hardware, you must perform a deep dive into your chemical feed. The “right” dryer is dictated by the “behavior” of your slurry.

Solids Content and Viscosity

High-solids slurries are more economical to dry because there is less water to evaporate. However, as solids increase, viscosity typically rises. You must determine:

- Can the slurry be pumped?

- Does it exhibit non-Newtonian behavior (thickening or thinning under stress)?

Particle Size Requirements

The end-use of your chemical dictates the particle size. Catalysts might require very fine particles, while ceramic precursors or detergents might require larger, free-flowing granules.

Heat Sensitivity

Many chemicals degrade, discolor, or lose reactivity if exposed to high temperatures. This determines whether you need a Co-Current, Counter-Current, or Mixed-Flow configuration.

3. Selecting the Atomization Method

The atomizer is the “heart” of the spray dryer. For chemical slurries, there are three primary choices:

A. Rotary Atomizers (Centrifugal)

Best for high-capacity plants. They use a high-speed spinning disk to fling the slurry into droplets.

- Pros: Handles abrasive slurries well; flexible flow rates; less prone to clogging.

- Cons: Higher capital cost; produces a wider particle size distribution.

B. Pressure Nozzles (Single-Fluid)

Uses high pressure (up to 250 bar) to force liquid through a small orifice.

- Pros: Produces coarse, narrow-sized granules with high bulk density.

- Cons: Highly susceptible to erosion from abrasive chemicals; prone to plugging if solids aren’t finely milled.

C. Two-Fluid Nozzles (Pneumatic)

Uses compressed air to shear the liquid into droplets.

- Pros: Ideal for very viscous slurries or producing extremely fine particles in pilot-scale setups.

- Cons: High energy consumption due to compressed air requirements.

4. Choosing the Air Flow Configuration

How the air meets the product determines the thermal history of the particle.

| Configuration | Air & Product Direction | Best For |

| Co-Current | Same direction | Heat-sensitive chemicals (droplets meet hottest air when they are wet and cool). |

| Counter-Current | Opposite directions | Heat-stable chemicals requiring very low residual moisture. |

| Mixed-Flow | Combination | Large chambers where coarse particles need longer residence time. |

5. Material of Construction (MoC)

Chemical slurries are often aggressive. Choosing the wrong MoC can lead to batch contamination or catastrophic equipment failure.

- Standard: Stainless Steel 304/316L.

- Corrosive Environments: For acidic or high-chloride slurries, we utilize Hastelloy, Duplex Stainless Steel, or specialized polymer linings.

- Abrasive Slurries: For ceramics or minerals, critical parts (like nozzle tips or atomizer wheels) should be reinforced with Tungsten Carbide or Silicon Carbide.

6. Safety and Environmental Compliance

Chemical drying often involves hazardous elements. AKSH Engineering prioritizes three safety pillars:

- Explosion Protection: If your chemical dust is explosive (ST1 or ST2 class), the dryer must be equipped with explosion relief vents, suppression systems, or operate in a Closed-Loop Nitrogen environment.

- Emission Control: To meet environmental norms, the exhaust gas must be scrubbed. We offer a combination of High-Efficiency Cyclones, Bag Filters, and Wet Scrubbers.

- Containment: For toxic chemicals, the system must be hermetically sealed to prevent dust leakage into the workspace.

7. The AKSH Engineering Advantage: Why Partner With Us?

At AKSH Engineering Systems Pvt. Ltd., we don’t believe in “off-the-shelf” solutions. Every chemical slurry is unique, and our engineering process reflects that.

Our Engineering Excellence:

- Custom Scaling: We design systems ranging from laboratory R&D units to massive industrial towers.

- Energy Efficiency: Our dryers incorporate heat recovery systems (Air-to-Air heat exchangers) to reduce your carbon footprint and operational costs.

- Pilot Plant Testing: We offer testing facilities to validate your slurry behavior before you commit to a full-scale build. This eliminates “guesswork” in the drying kinetics.

Conclusion

Choosing the right spray dryer for chemical slurries is a balance between material science, mechanical engineering, and thermodynamics. By focusing on your slurry’s specific rheology, the required final particle morphology, and safety requirements, you ensure a system that delivers consistent quality for decades.

Ready to optimize your chemical production?

The team at AKSH Engineering Systems Pvt. Ltd. is ready to help you design a system tailored to your specific chemical challenges.