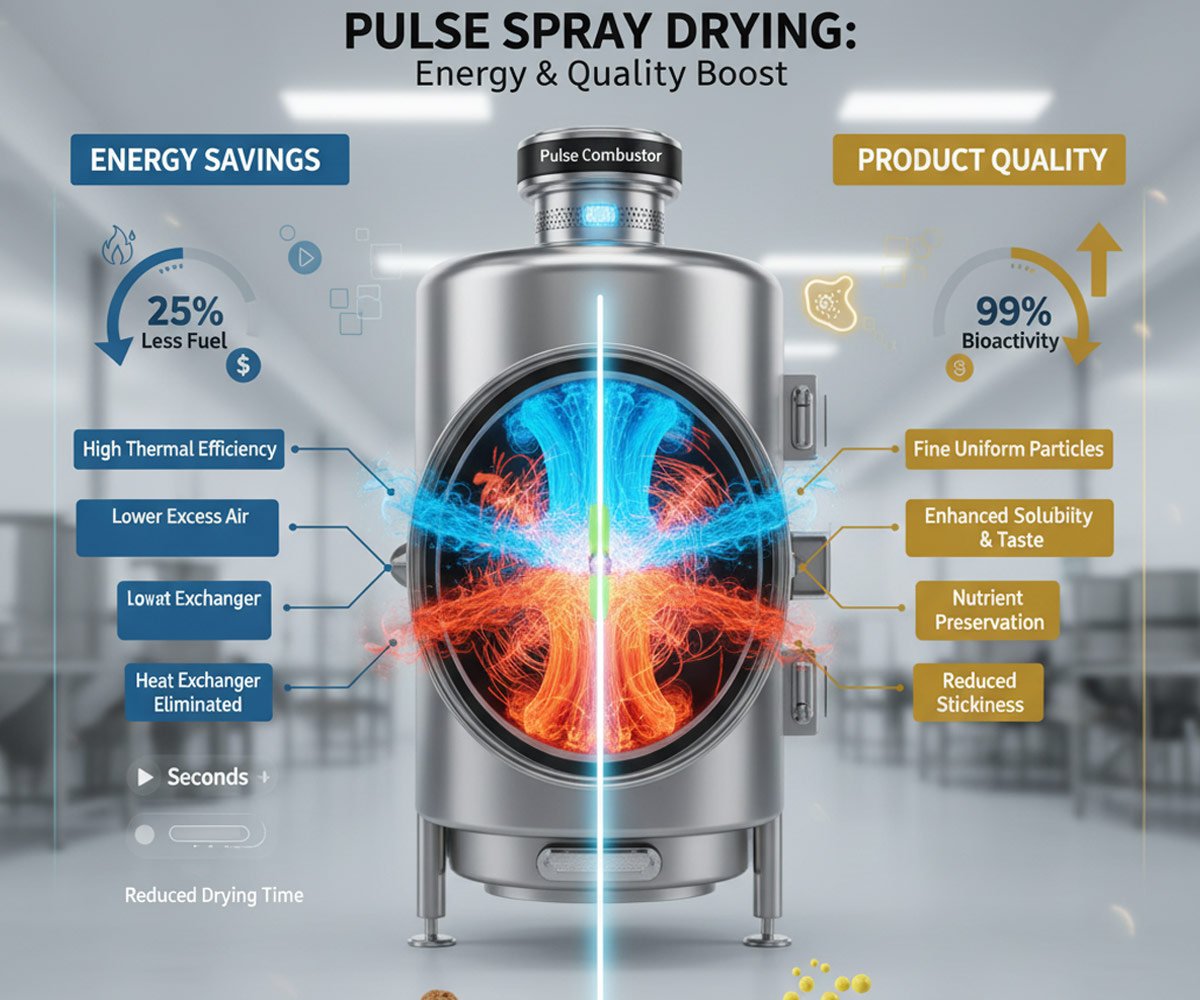

Pulse spray drying, particularly through the use of Pulse Combustion Spray Dryers (PCDs), is an advanced technology that offers significant advantages over conventional spray drying, particularly in enhancing energy savings and product quality in food processing.

Here is a breakdown of how this innovative technique achieves superior results:

How Pulse Spray Drying Works (The Mechanism)

Unlike conventional spray dryers that rely on a continuous flow of hot air generated by a steady burner, pulse spray drying uses a unique heat source: a pulse combustor.

- Pulse Combustion: The process generates heat through a series of rapid, periodic (pulsed) combustion cycles (typically 60 to 120 times per second) within a specially designed chamber.

- High-Intensity Sound Waves: The rapid combustion cycles create high-intensity, low-frequency pressure (acoustic) waves and intense, turbulent flow.

- Atomization and Drying:

- The liquid food feed is injected directly into this turbulent, high-velocity gas stream.

- The combination of high-velocity flow and the powerful acoustic energy atomizes the feed into exceptionally fine droplets, often eliminating the need for traditional nozzles or rotary atomizers.

- The rapid, turbulent mixing of the hot gas and the fine droplets leads to extremely high heat and mass transfer rates.

Boosting Energy Savings

Pulse spray drying inherently offers superior energy efficiency compared to conventional methods:

- Higher Thermal Efficiency: Pulse combustors can achieve near-stoichiometric combustion (near-perfect air-to-fuel ratio), leading to a much higher thermal efficiency in converting fuel energy into usable heat.

- Lower Excess Air Requirements: Conventional dryers require a large excess of air to temper the heat and ensure complete combustion. PCDs operate with less excess air, meaning less gas needs to be heated and exhausted, directly saving energy.

- Reduced Drying Time: The intense turbulence and high heat/mass transfer rates drastically reduce the time required for drying (often seconds or less). Shorter process time translates directly to lower overall energy use per unit of product.

- Direct Drying: The hot combustion gases are mixed directly with the material being dried, eliminating the heat exchanger typically required in conventional systems, thus reducing heat loss.

Enhancing Product Quality

The unique operating environment of the pulse dryer addresses several quality challenges associated with traditional methods:

- Protection of Heat-Sensitive Materials: Although the peak temperature in the combustion chamber is very high, the short residence time and the evaporative cooling effect caused by the rapid, uniform atomization mean the product particles themselves remain at a much lower temperature (closer to the wet-bulb temperature). This minimizes thermal degradation, preserving sensitive nutrients, flavors, and colors (e.g., in fruit juice powders, microencapsulated vitamins).

- Improved Powder Characteristics: The powerful atomization achieved via acoustic energy creates a very fine and uniform particle size distribution. This is ideal for enhancing properties like:

- Solubility and Dispersibility: Finer, more uniform particles dissolve faster and more completely, improving the consumer experience (e.g., instant beverages).

- Reduced Stickiness: Rapid, turbulent drying effectively controls the surface temperature of sticky, high-sugar materials, reducing wall build-up and increasing yield.

- Preserved Bioactivity: For ingredients like probiotics or enzymes, the combination of low product temperature and extremely fast drying time is less damaging, resulting in higher retention of functional bioactivity in the final powder.

In summary, pulse spray drying leverages acoustic energy and turbulent flow to atomize and dry food products with exceptional speed and thermal efficiency, making it an advanced, sustainable choice for processing high-quality, heat-sensitive food ingredients.

Would you like to see a direct comparison of the particle properties (like size or solubility) of a product dried using pulse spray drying versus conventional spray drying?