This comprehensive industry report explores the transformative impact of spray drying technology on the pharmaceutical and nutraceutical sectors, highlighting the precision-engineered solutions provided by AKSH Engineering Systems Pvt Ltd.

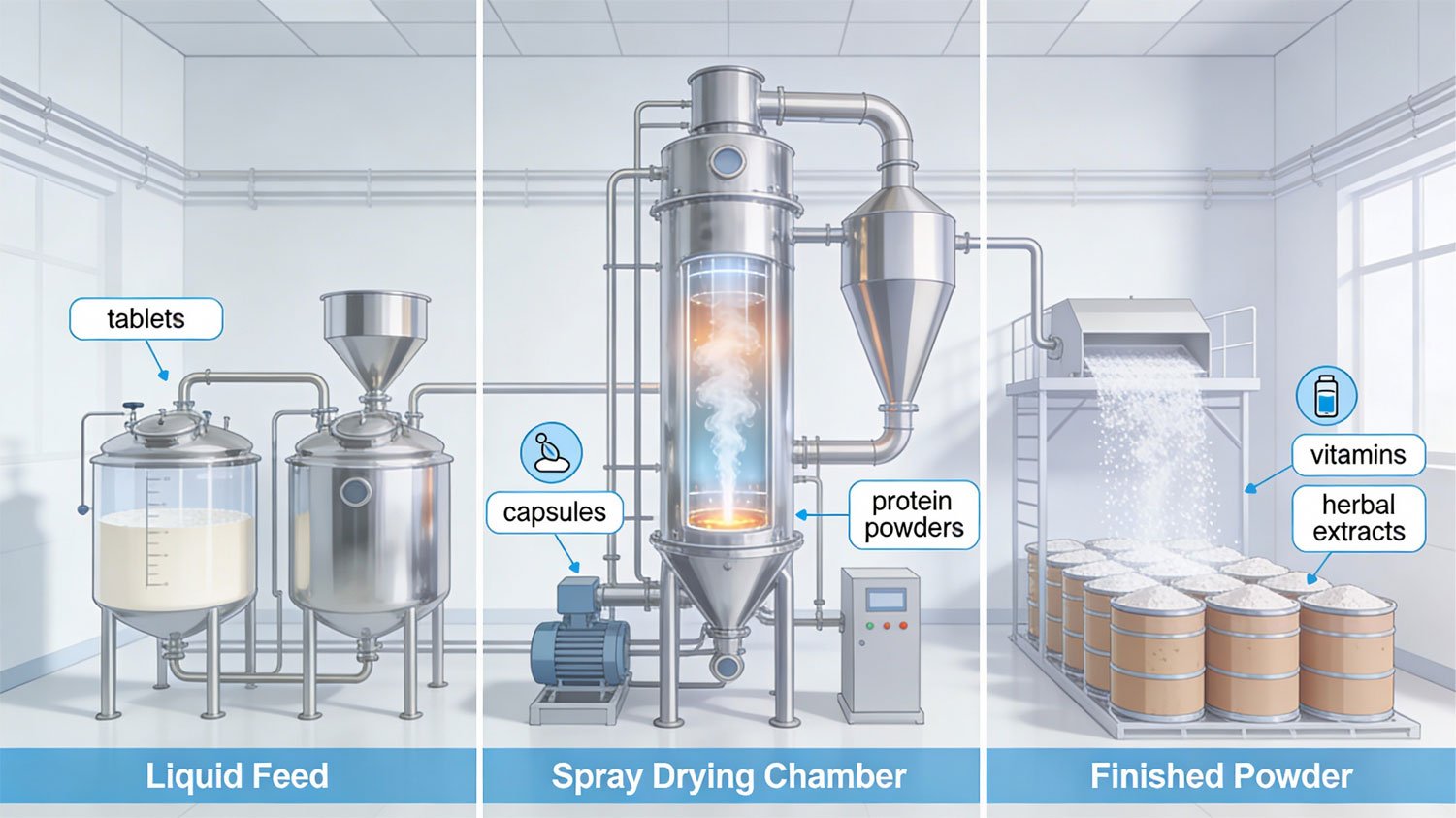

Our Product Pilot Spray Dryer serves as the critical bridge in this journey, allowing manufacturers to transform complex liquids into high-performance powders with surgical accuracy.

Precision in Every Particle: How Spray Dryer Plants Transform Pharmaceutical and Nutraceutical Production

In the highly regulated worlds of pharmaceuticals and nutraceuticals, the difference between a life-saving drug and an ineffective compound often boils down to a few microns. The ability to control particle size, morphology, and stability is paramount.

As a leader in industrial thermal processing, AKSH Engineering Systems has witnessed a paradigm shift: manufacturers are moving away from traditional batch drying toward Spray Drying. This technology isn’t just a drying method; it is a sophisticated particle-engineering tool that solves the industry’s most complex formulation challenges.

1. The Challenge: Heat Sensitivity and Bioavailability

Pharmaceutical and nutraceutical ingredients are notoriously difficult to process. They often face two major hurdles:

- Thermal Degradation: Active Pharmaceutical Ingredients (APIs) and vitamins often break down when exposed to heat for long periods.

- Poor Solubility: Many modern drugs are “Biopharmaceutics Classification System (BCS) Class II,” meaning they are poorly soluble in water, making it hard for the human body to absorb them.

How Spray Drying Solves This: Because the evaporation process in a spray dryer happens in milliseconds, the “wet bulb temperature” stays low. The product itself never reaches the high temperature of the inlet air, protecting delicate molecules like proteins, enzymes, and probiotics.

2. Enhancing Bioavailability through Solid Dispersions

One of the most revolutionary applications of AKSH Engineering spray dryers is the creation of Amorphous Solid Dispersions (ASDs).

By dissolving a poorly soluble drug and a polymer in a common solvent and spray drying them together, we “trap” the drug in an amorphous (non-crystalline) state. This significantly increases the surface area and the rate of dissolution in the digestive tract, ensuring that the patient receives the full therapeutic benefit of the dose.

3. Micro-Encapsulation: Protecting the “Active”

In the nutraceutical industry, many ingredients—such as Omega-3 oils, flavors, and antioxidants—are prone to oxidation or have unpleasant tastes.

The AKSH Solution:

Through spray drying, we can perform Micro-Encapsulation. The active ingredient is mixed with a coating material (like maltodextrin or gum arabic). As the droplet dries, the coating forms a protective shell around the core.

- Taste Masking: Bitter-tasting vitamins are “hidden” inside a neutral shell.

- Controlled Release: The shell can be engineered to dissolve only at a specific pH level in the stomach or intestines.

- Shelf-Life Extension: Delicate oils are protected from oxygen and light, preventing rancidity.

4. Engineering for Pharma-Grade Standards (cGMP)

Pharmaceutical production requires a level of hygiene far beyond standard industrial applications. AKSH Engineering Systems designs plants specifically to meet Current Good Manufacturing Practices (cGMP):

A. Material Integrity

All contact parts are manufactured from SS316L stainless steel, polished to a mirror finish ($Ra < 0.4 \mu m$). This prevents cross-contamination and ensures that no residue sticks to the walls.

B. Clean-In-Place (CIP) Systems

Manual cleaning of a large spray dryer is risky and time-consuming. Our plants feature integrated CIP manifolds and high-pressure rotating nozzles that wash every inch of the system automatically, ensuring validated cleanliness between batches.

C. Aseptic Processing

For injectable drugs, we design Closed-Loop Systems using Nitrogen as the drying medium. This ensures the environment is oxygen-free (preventing explosions with solvents) and sterile.

5. Key Components in Pharma-Nutra Spray Dryers

| Component | Role in Pharma/Nutra |

| HEPA Filtration | Ensures the drying air is 99.97% free of microbes and contaminants. |

| Dehumidifiers | Removes moisture from ambient air to ensure consistent drying even in monsoon seasons. |

| Bag Filters with Sonic Horns | Ensures 100% recovery of high-value APIs without manual shaking. |

| Explosion Vents | Vital for safety when processing powders that may be combustible. |

6. The Rise of “Instant” Nutraceuticals

The modern consumer demands convenience. Whether it’s a protein shake or a collagen powder, the product must dissolve instantly without clumping.

AKSH Multi-Stage Spray Dryers utilize a secondary fluid bed. This process allows small particles to “agglomerate” or stick together into larger, porous granules. These “snowball-like” structures allow water to wick into the powder quickly, providing the “instant” solubility that defines premium nutraceutical brands.

7. Why Partner with AKSH Engineering Systems?

At AKSH, we bridge the gap between complex science and industrial reality. Our pharmaceutical spray dryers are equipped with:

- 21 CFR Part 11 Compliant Automation: Digital records and signatures for total traceability.

- Scalability: We help you move from 100-gram lab samples to 1,000-kg commercial batches with predictable results.

- Precision Atomization: Choose between ultrasonic, two-fluid, or rotary atomization based on your specific molecule’s needs.

8. How the AKSH Pilot Spray Dryer Accelerates R&D

Moving directly from a beaker to a 10-ton-per-day plant is a recipe for expensive failure. This is where the AKSH Product Pilot Spray Dryer becomes your most valuable asset.

Bridging the Gap (Scale-Up)

Our pilot units (with capacities starting from 3 kg/hr) are designed with the exact same geometry and thermodynamics as our industrial-scale towers. This means the data you gather in the lab—inlet temperatures, feed rates, and nozzle pressures—can be scaled up with 99% accuracy to full production.

Conclusion

The transformation of liquid medicine and nutrients into stable, bioavailable, and consumer-friendly powders is the hallmark of modern health science. A spray dryer is no longer just “equipment”—it is the key to unlocking the next generation of pharmaceutical and nutraceutical breakthroughs.