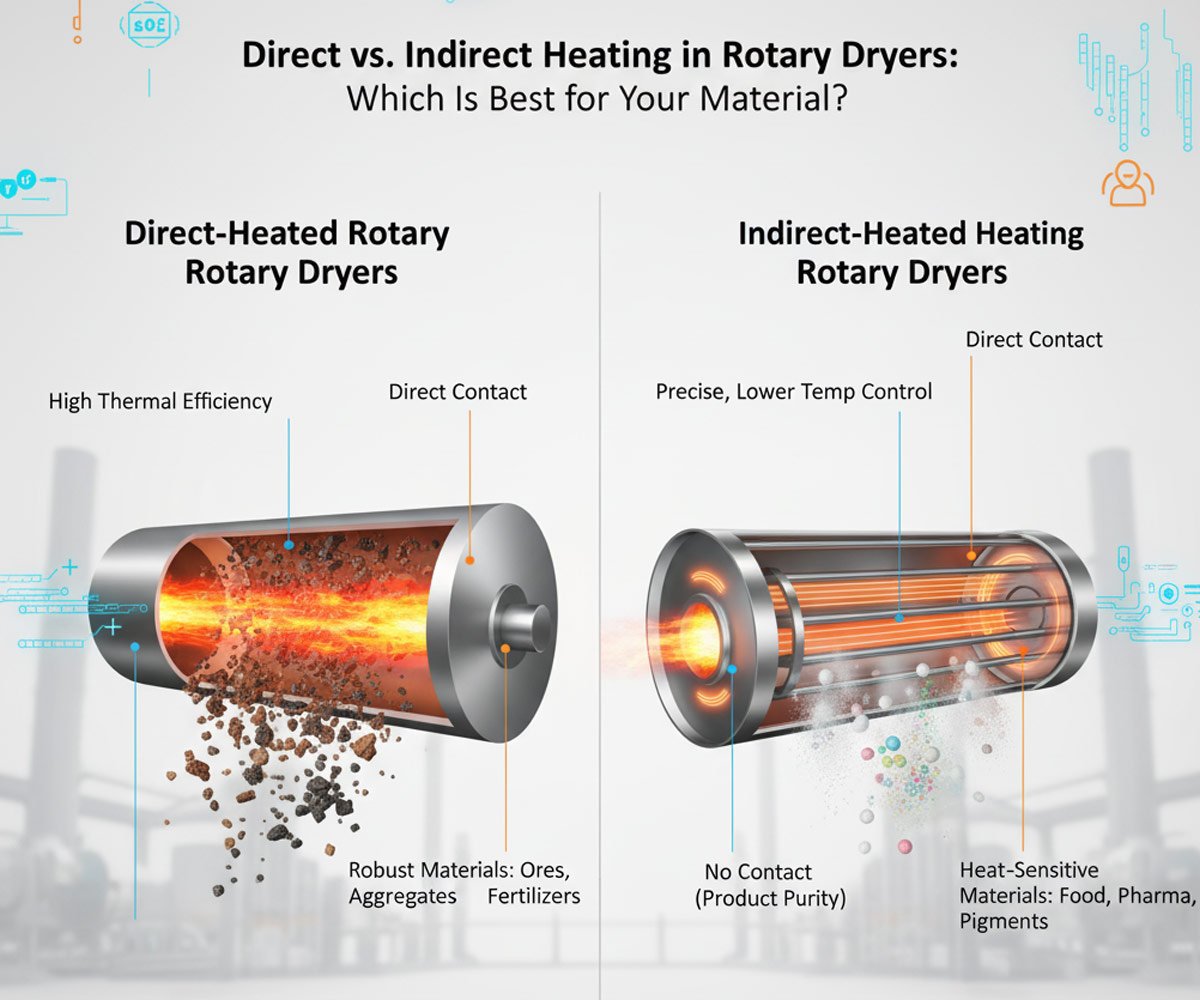

The choice between a direct and an indirect rotary dryer depends entirely on the material being processed and its sensitivity to heat and potential contamination from combustion gases. The core difference lies in whether the material and the heat source are in physical contact.

Direct-Heated Rotary Dryers (Convective Heat Transfer)

In a direct-heated dryer, the heated gas (typically a mix of air and combustion gases) is brought into direct contact with the material being dried.1 This is the most common and thermally efficient type.

| Feature | Description |

| Heat Transfer | Mainly convection. Hot gas directly touches the material. |

| Contact | Direct contact between material and heated air/combustion gases. |

| Efficiency | High efficiency due to immediate and thorough heat transfer. |

| Best For | Robust, non-flammable, and heat-tolerant materials where contamination is not an issue. |

| Examples | Minerals, Ores, Sand, Aggregates, Coal, most Fertilizers. |

Analogy: This is like drying clothes in a clothes dryer where the hot air blows directly over the fabric.

Indirect-Heated Rotary Dryers (Conductive/Radiant Heat Transfer)

In an indirect-heated dryer, the heat source (like a burner flame or steam) is isolated from the material.2 The heat is transferred through the shell of the drum or through internal tubes, meaning the material does not touch the combustion gases.3

| Feature | Description |

| Heat Transfer | Mainly conduction (through the drum wall) and radiation. |

| Contact | No direct contact between the material and the combustion gases. |

| Efficiency | Lower efficiency than direct heating, as heat transfer is less immediate. |

| Best For | Heat-sensitive, flammable, or chemically reactive materials that require precise temperature control or must remain free of contamination. |

| Examples | Specialty Chemicals, Pigments, Carbon Black, certain delicate Food products (e.g., starches), materials requiring an inert atmosphere. |

Analogy: This is like baking in an oven where the heat source (flame/element) is separated from the food by the oven wall, heating the food via radiation and conduction.4

Which is Best for Your Material?

The choice ultimately depends on two main criteria:

- Heat Sensitivity: For materials that will degrade, melt, or lose nutritional value at high temperatures (like most food products, pharmaceuticals, or delicate chemicals), Indirect Heating is preferred to avoid overheating.

- Contamination Risk: If the material’s purity is critical (e.g., food, pharmaceuticals, or materials that react with combustion products like 5$\text{CO}_2$), Indirect Heating is necessary to prevent contamination.6

- Volume & Durability: For high-volume, abrasive, and durable products that can withstand higher temperatures and direct gas contact, Direct Heating is the most efficient and economical choice.

| Material Characteristic | Preferred Dryer Type | Why? |

| High Durability, High Volume | Direct | Maximum thermal efficiency and high capacity. |

| Heat-Sensitive / Delicate | Indirect | Lower, more controlled product temperature to prevent degradation. |

| Requires Purity / Inert Atmosphere | Indirect | Isolates the product from combustion gases. |