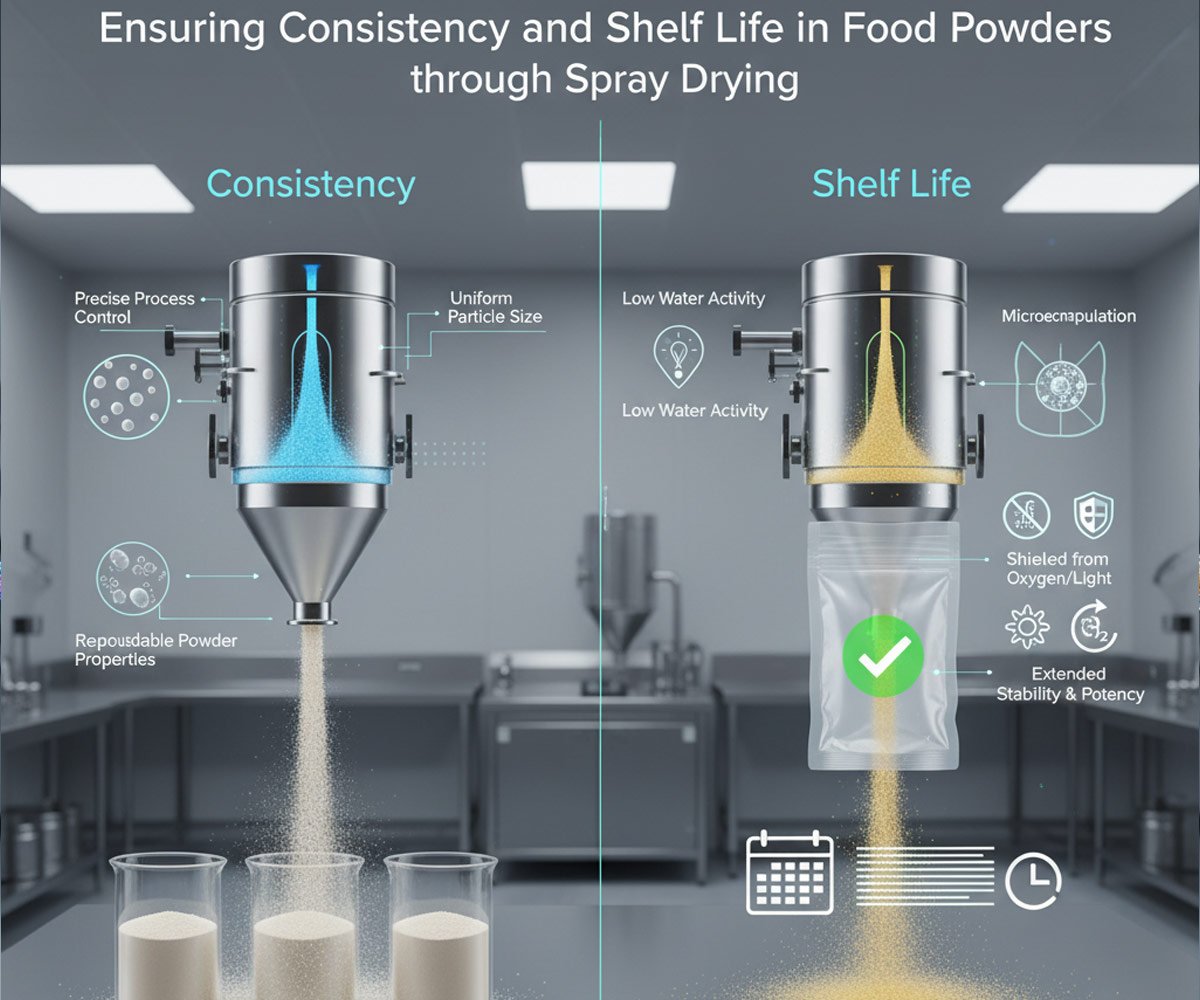

Ensuring consistency and maximizing shelf life are paramount for food powders, and spray drying is a cornerstone technology for achieving both. The ability to precisely control the drying process allows manufacturers to produce powders that consistently meet quality standards and remain stable over extended periods.

Here’s how spray drying ensures consistency and shelf life in food powders:

Ensuring Consistency in Food Powders

Consistency in food powders refers to uniform properties across batches, including particle size, moisture content, bulk density, and solubility. Spray drying achieves this through:

- Precise Process Control:

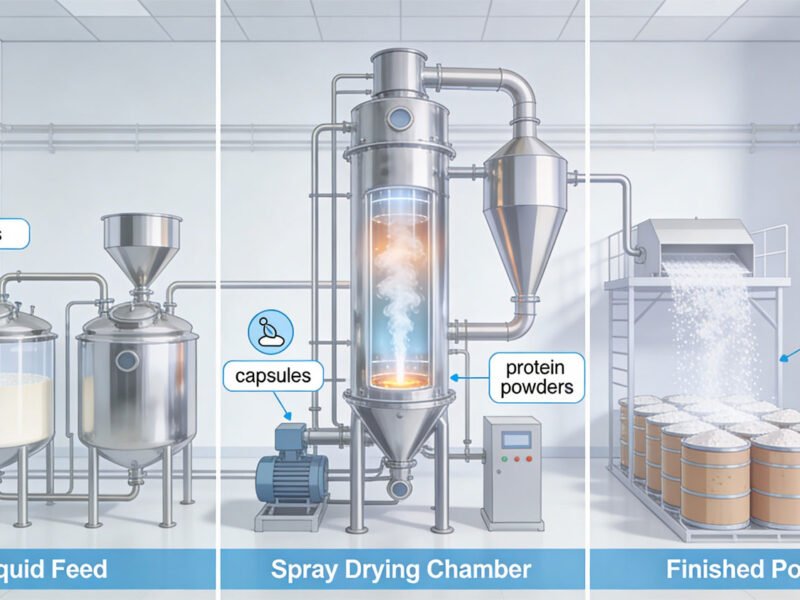

- Automated Systems: Modern spray dryers are equipped with advanced sensors and control systems (PID controllers, PLC) that maintain parameters like inlet/outlet air temperature, feed rate, and atomization pressure within very narrow ranges. This minimizes batch-to-batch variations.

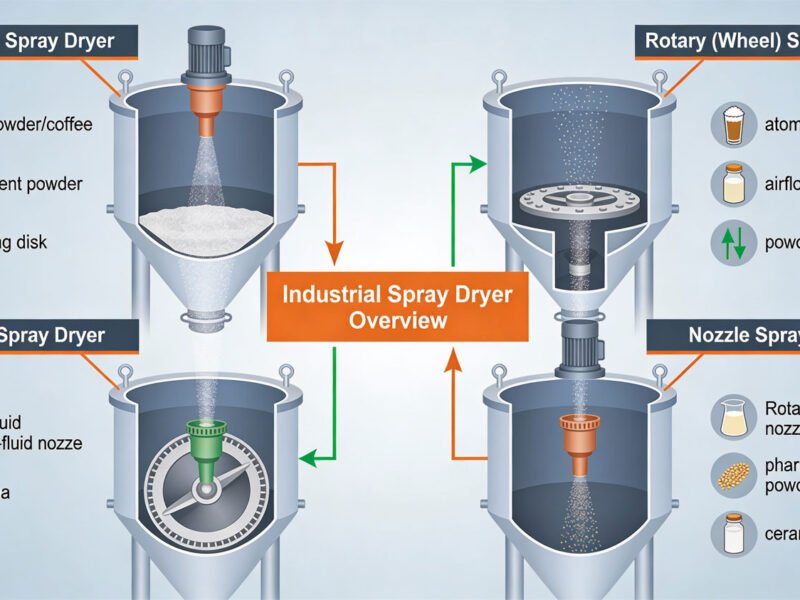

- Nozzle/Atomizer Technology: Advanced atomizers (rotary discs or two-fluid nozzles) provide highly uniform droplet size distribution. Since the final particle size is directly related to droplet size, this ensures consistent powder characteristics.

- Rapid and Uniform Drying:

- Short Residence Time: The very short residence time (seconds) of droplets in the drying chamber ensures that all particles experience similar drying conditions, preventing over-drying or under-drying of different parts of the batch.

- Homogeneous Heat and Mass Transfer: The fine atomization and turbulent flow within the chamber promote efficient and even heat and mass transfer, leading to uniform moisture removal from all particles.

- Reproducible Powder Properties:

- Particle Size and Morphology: Consistent drying leads to consistent particle size, which directly impacts mouthfeel, dispersibility, and mixing properties in food applications.

- Bulk Density: Uniform drying and particle formation result in consistent bulk density, crucial for packaging, storage, and dosage accuracy in recipes.

Ensuring Shelf Life in Food Powders

Shelf life is primarily determined by preventing degradation reactions (e.g., oxidation, microbial growth, enzymatic activity). Spray drying significantly extends shelf life by:

- Reducing Water Activity (Moisture Content):

- Inhibiting Microbial Growth: Spray drying efficiently reduces the moisture content of the food product to very low levels (typically 1-5%). This drastically lowers the water activity (aw), which is the free water available for microbial growth. Below an aw of ~0.6, most bacteria, yeasts, and molds cannot grow, preventing spoilage.

- Slowing Chemical/Enzymatic Reactions: Low water activity also significantly slows down undesirable chemical reactions (like non-enzymatic browning) and enzymatic activity that can degrade flavor, color, and nutrients over time.

- Microencapsulation and Protection:

- Barrier Formation: During spray drying, a carrier material (like maltodextrin, gum arabic) can be used to encapsulate sensitive core ingredients (e.g., flavors, Omega-3 oils, probiotics). This forms a protective barrier around the core.

- Protection from Oxygen and Light: The encapsulating matrix protects the sensitive ingredients from external factors like oxygen and light, which are primary causes of oxidation and degradation (e.g., rancidity in fats, loss of vitamins). This is critical for maintaining flavor and nutritional integrity.

- Low Thermal Impact:

- Minimizing Heat Degradation: Although spray drying uses hot air, the drying time is extremely short. This brief exposure to heat minimizes the thermal degradation of heat-sensitive components like vitamins, enzymes, and delicate flavor compounds, preserving their integrity and extending their functional life.

- Aseptic Processing (for sensitive products):

- Reduced Contamination: For highly sensitive or sterile products (like infant formula), spray dryers can be designed for aseptic operation, minimizing the risk of microbial contamination during the drying process itself, further enhancing shelf life and safety.

By effectively controlling moisture, protecting sensitive components through encapsulation, and minimizing thermal damage, spray drying is an indispensable technology for producing a wide array of consistent, high-quality food powders with extended shelf lives, meeting both consumer and industry demands.