The future of spray drying in the food industry is marked by a focus on preserving sensitive nutrients, enhancing functional ingredients, and achieving greater energy efficiency through advanced technology.

The global market for spray drying in food processing is experiencing strong growth, driven by the demand for high-quality, shelf-stable, and convenient powdered foods like infant formula, dairy powders, and functional food ingredients.

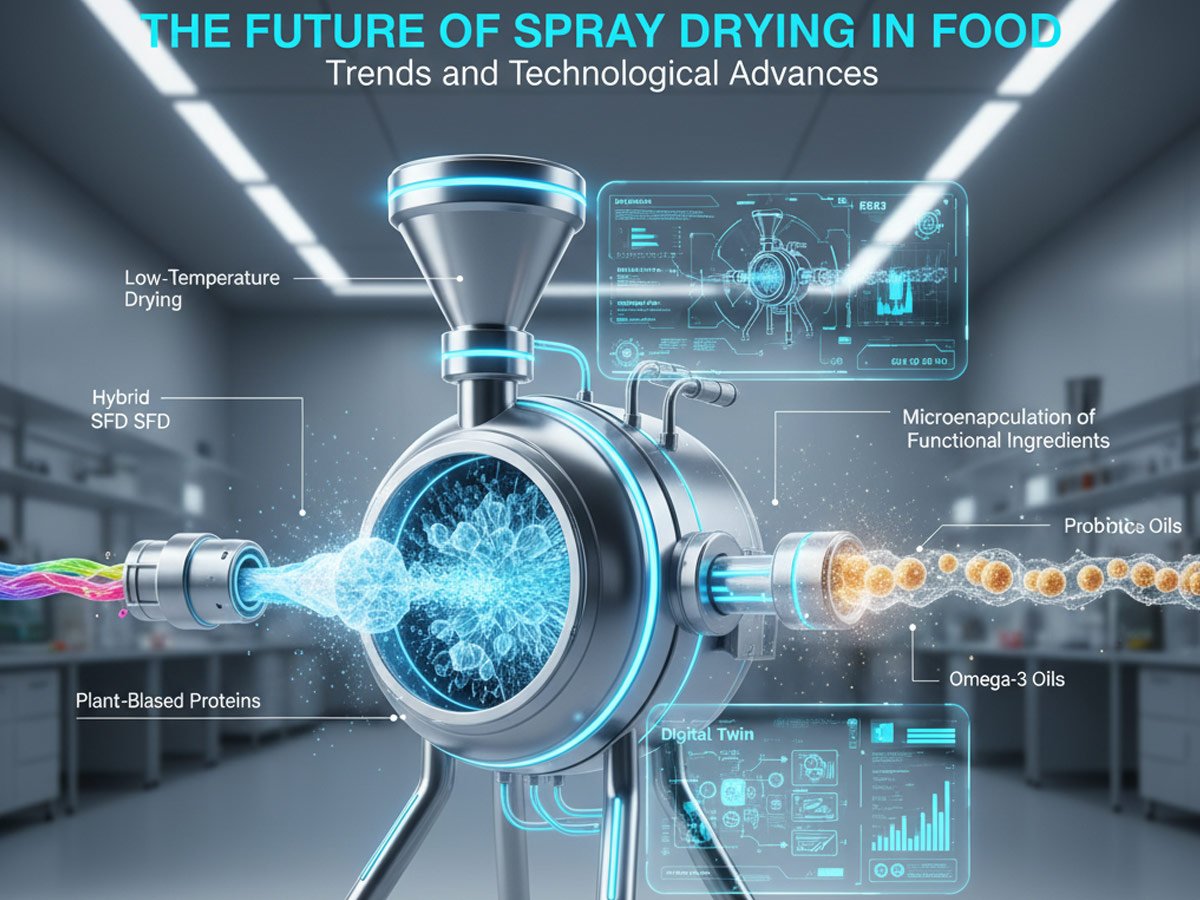

Here are the major trends and technological advances shaping the future of spray drying in the food sector:

Future Trends: Focus on Quality and Functionality

1. Microencapsulation of Functional Ingredients

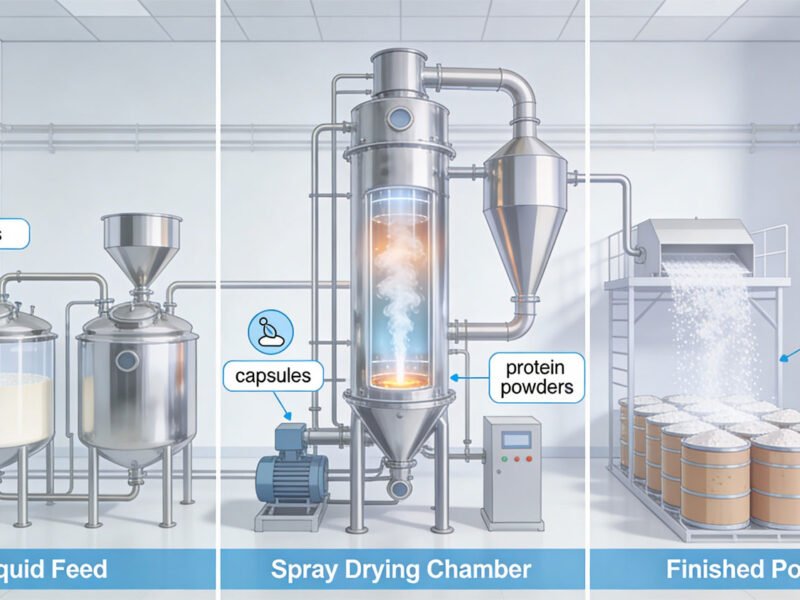

- Trend: This is the most significant growth area. Spray drying is used to create tiny capsules (microcapsules) that shield sensitive bioactive compounds.

- Applications:

- Probiotics: Encapsulation protects live bacteria from the high heat of the process and the harsh acidic environment of the stomach, ensuring their viability until they reach the gut.

- Essential Oils & Flavors: It prevents the loss of volatile aromas and protects flavor oils (like fish oil with Omega-3s) from oxidation, significantly extending shelf life and masking undesirable tastes.

- Vitamins & Antioxidants: Protection against degradation from light, oxygen, and moisture to maintain high nutritional value in fortified foods.

2. Low-Temperature and Hybrid Drying

- Trend: Moving away from high-temperature conventional drying to minimize thermal degradation of highly sensitive ingredients.

- Technological Advances:

- Spray Freeze Drying (SFD): A hybrid technique that combines spray atomization with freeze-drying. The droplets are flash-frozen and then dried by sublimation at low temperatures and pressures. This yields highly porous powders with exceptional re-hydration properties and minimal nutrient loss, ideal for high-value food ingredients.

- Dehumidified Air Drying: Using very dry, but cooler, air to increase the drying potential without raising the temperature, allowing sensitive materials (like certain enzymes or colorants) to be processed safely.

3. Focus on Plant-Based Proteins and Novel Foods

- Trend: The shift toward sustainable and plant-based diets is driving the need for efficient drying of new protein sources.

- Applications: Spray drying is crucial for converting liquid protein isolates from sources like peas, soy, or algae into fine, easily dissolvable, high-quality protein powders used in supplements and food fortification.

Technological Advances: Smarter, More Efficient Equipment

4. Integration of Industry 4.0 and Digital Twins

- Trend: Utilizing connectivity, data, and simulation to achieve unprecedented levels of process control and efficiency.

- Advancement:

- Real-Time Monitoring: Smart sensors (IoT) collect live data on moisture, temperature, and particle size.

- Digital Twin: A virtual replica of the physical dryer is used to predict product quality and energy consumption, allowing the system to automatically adjust parameters to optimize for maximum yield and minimum energy use (Advanced Process Control).

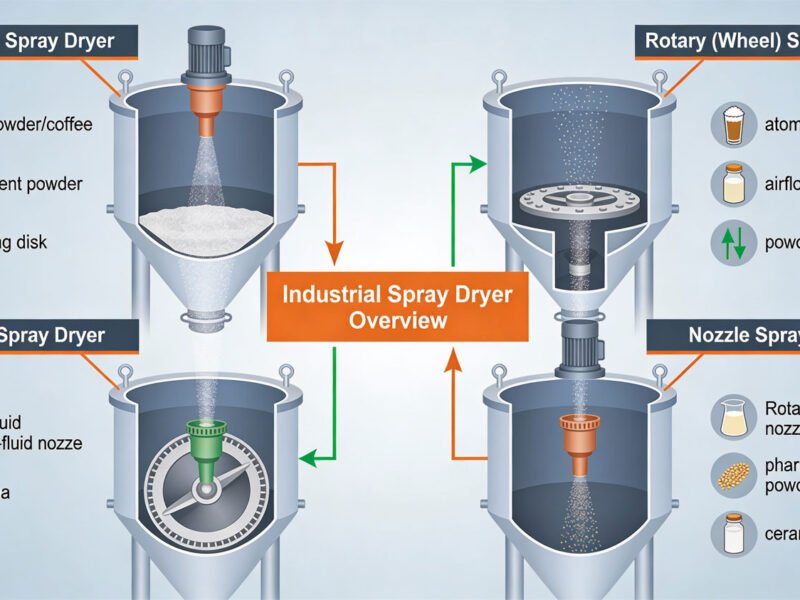

5. Cleaner and More Versatile Atomization

- Trend: Innovations in the nozzle or disc that breaks the liquid feed into droplets, aiming for better control over particle properties.

- Advancement: Next-generation atomizers and multi-fluid nozzles offer finer control over droplet size distribution, which directly influences the final powder’s texture, bulk density, and dissolution rate (e.g., creating instantized powders with better solubility).

6. Sustainable and Cost-Effective Operations

- Trend: Reducing the significant energy consumption and waste associated with the drying process.

- Advancement:

- Closed-Loop Systems: Used when drying with organic solvents (less common in food but applicable to flavor extraction) or inert gases like nitrogen, these systems recover the drying medium, which enhances safety and reduces emissions.

- Energy Recovery Systems: Advanced heat exchange technologies capture waste heat from the exhaust air and use it to pre-heat the inlet air or concentrate the feed, drastically improving overall energy efficiency.

In summary, the future of spray drying in the food industry is an intersection of precision engineering (low-temp, hybrid methods) and digital intelligence (Digital Twins, AI control), all aimed at producing functional, high-quality, and highly stable powdered food ingredients in the most sustainable way possible.