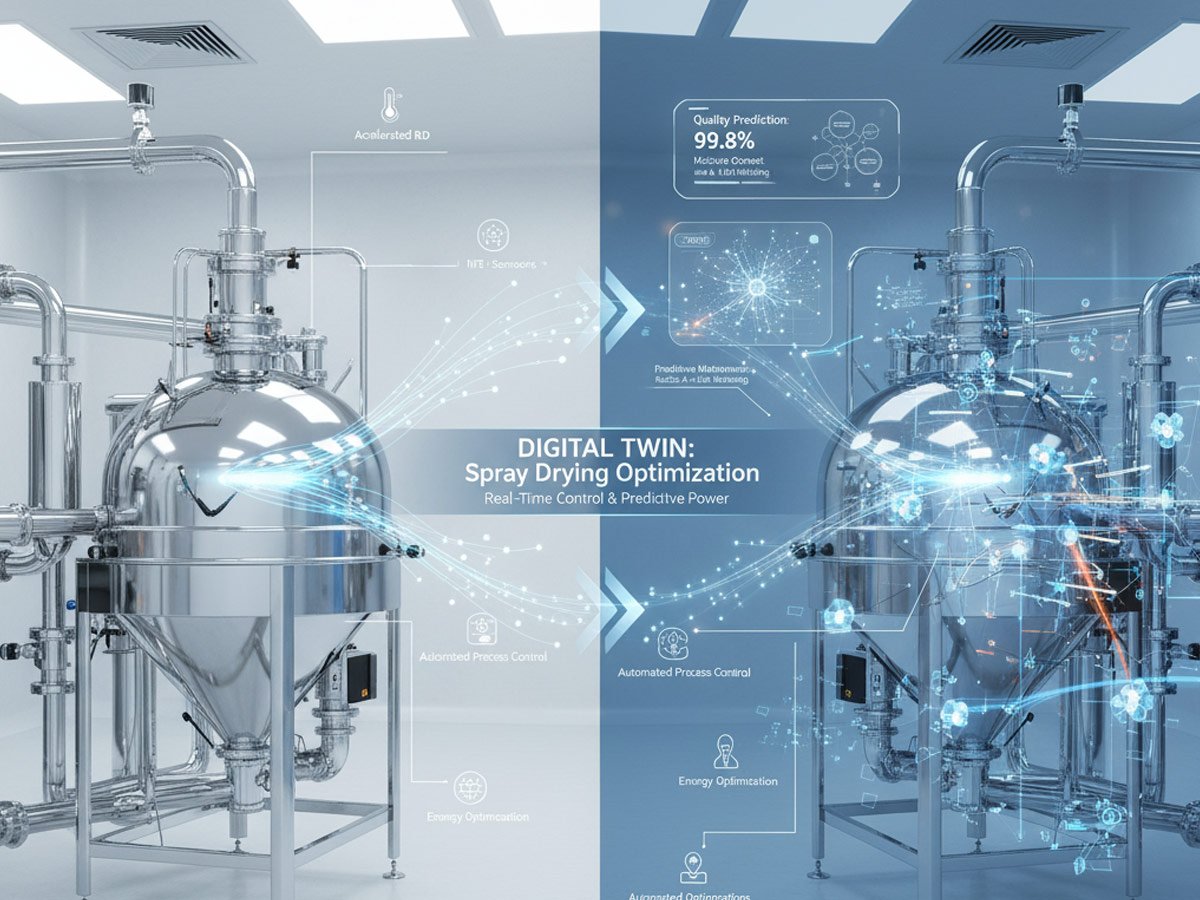

Key Optimization Benefits of Digital Twin in Spray Drying

1. Real-Time Process Optimization and Control

The Digital Twin enables an advanced level of control far beyond traditional automation.

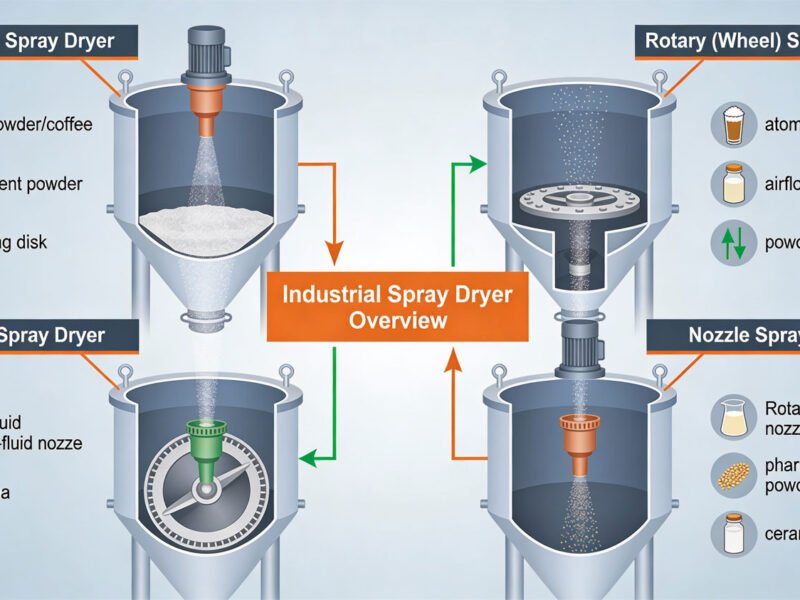

- Advanced Process Control (APC): The twin continuously processes real-time data on parameters like inlet/outlet temperature, feed rate, and airflow. It uses predictive models to automatically adjust control setpoints (e.g., every few seconds) to maintain ideal drying conditions, even as raw material quality or ambient temperature fluctuates.

- Quality Prediction: It predicts critical product quality attributes (like residual moisture content or particle size distribution) before the powder is collected. This allows operators to make immediate adjustments to ensure every batch meets specifications, reducing waste and re-work.

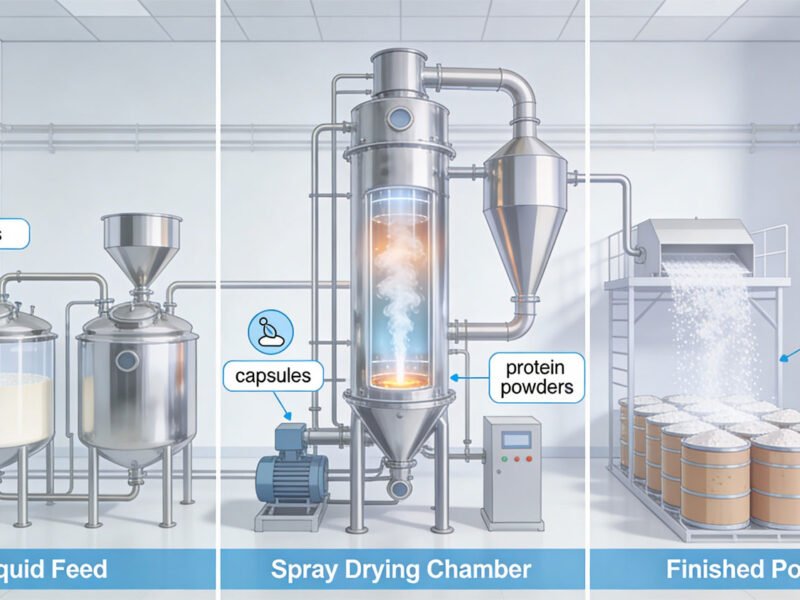

2. Accelerated Product Development and Scale-Up

Digital Twins drastically cut down the time and cost associated with R&D and manufacturing scale-up.

- Virtual Experimentation (Reduced Trial-and-Error): Manufacturers can simulate thousands of different formulations (e.g., varying excipient ratios in pharma, or carrier agents in food) and process conditions on the virtual twin. This identifies the optimal recipe and process parameters much faster, dramatically reducing the number of expensive, time-consuming physical tests required on the actual dryer.

- Faster Time-to-Market: Especially in the pharmaceutical industry, the ability to virtually test and validate processes can accelerate development and speed up regulatory submission times, quickly bringing critical drugs to market.

3. Predictive Maintenance and Operational Efficiency

By mimicking the physical system’s behavior, the Digital Twin can forecast equipment issues.

- Predictive Maintenance: It analyzes equipment data (vibration, heat, pressure drops) to detect early signs of component failure, such as a clogged nozzle or bearing wear. It then triggers an alert, allowing maintenance to be scheduled proactively rather than reactively, which can reduce unplanned downtime by over 45%.

- Energy Optimization (Sustainability): By identifying the most energy-efficient operating window that still delivers the desired product quality, the twin can optimize air flow rates and temperature. This can lead to a significant reduction in energy consumption per kilogram of product.

4. Risk Mitigation and Operator Training

The twin serves as a safe environment for both current and future operations.

- Fault Simulation: It allows engineers to simulate worst-case scenarios (e.g., sudden feed loss, power surge) to test the control system’s response and train operators on proper troubleshooting procedures without any risk to the actual, multi-million dollar equipment or product batch.

- Process Parameter Tuning: In high-stakes environments like pharmaceutical production, the twin is used to find tight operating margins safely, ensuring the process remains compliant and stable.