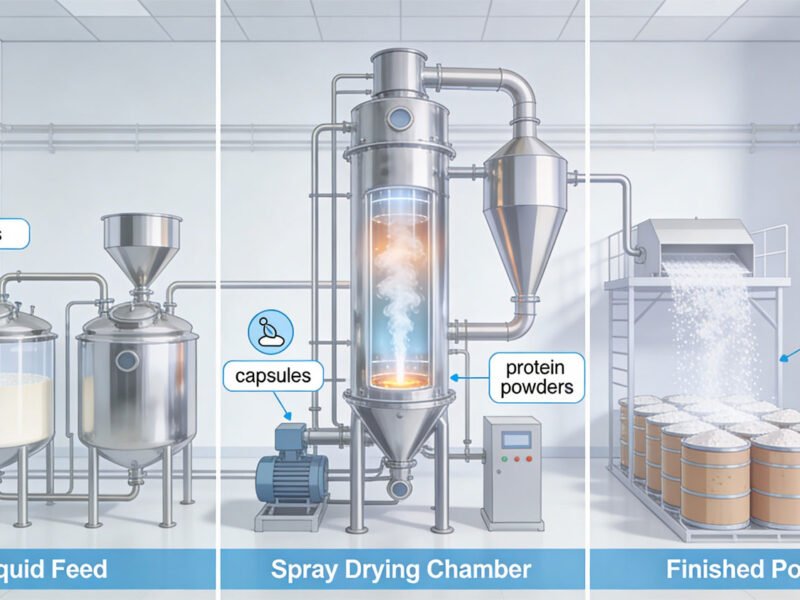

Industrial spray drying is notoriously energy-intensive. In many chemical, food, and pharmaceutical plants, the spray dryer alone can account for up to 60-70% of the total site energy consumption. With rising fuel costs and increasing pressure to reduce carbon footprints, optimizing thermal efficiency isn’t just an environmental goal—it’s a financial imperative.

At AKSH Engineering Systems Pvt. Ltd., we specialize in high-efficiency thermal processing. This comprehensive guide outlines actionable strategies to reduce energy consumption in your spray drying operations without compromising product quality.

1. Optimize the Feed Characteristics

Energy efficiency starts before the slurry even reaches the drying chamber. The more water you remove mechanically, the less you have to remove thermally.

Increase Solids Content

The relationship between feed solids and energy consumption is non-linear. Even a 1% increase in solids concentration can lead to a significant reduction in the total evaporation load.

- The Strategy: Use upstream processes like membrane filtration, vacuum evaporation, or high-efficiency centrifuges to concentrate the feed as much as possible.

- The Benefit: Less water to evaporate means lower fuel consumption and higher powder output per hour.

Pre-Heating the Feed

Heating the feed slurry using waste heat from other parts of the plant (or via a dedicated heat exchanger) reduces the “Sensible Heat” requirement inside the drying chamber.

- Technical Tip: Ensure the temperature remains below the point of product degradation or premature crystallization.

2. Maximize the Temperature Differential (ΔT)

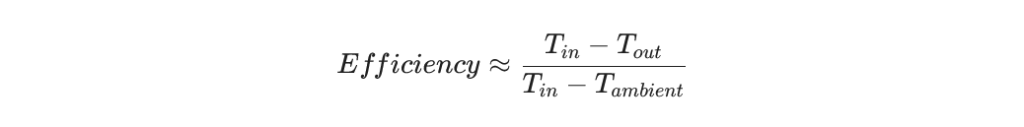

The efficiency of a spray dryer is largely governed by the difference between the Inlet Temperature (Tin) and the Outlet Temperature (Tout).

Raise the Inlet Temperature (Tin)

Within the limits of your product’s heat sensitivity, the inlet temperature should be as high as possible.

- Why? High-temperature air carries more energy and can evaporate moisture faster, requiring less total air volume.

Lower the Outlet Temperature (Tout)

The outlet temperature is often kept higher than necessary “just to be safe.” However, every degree Celsius exhausted is wasted energy.

- The Strategy: Implement precision controls (like PLC-based PID loops) to bring the Tout as close to the dew point as safely possible without causing damp powder or wall sticking.

3. Advanced Heat Recovery Systems

For large-scale industrial dryers, the exhaust air contains a massive amount of low-grade thermal energy. Recovering this is the “holy grail” of energy saving.

Air-to-Air Heat Exchangers

AKSH Engineering recommends installing heat exchangers that use the hot exhaust air to pre-heat the incoming ambient process air.

- Recuperators: Can recover 15-25% of the heat that would otherwise be lost to the atmosphere.

- Run-around Coils: Useful if the intake and exhaust are located far apart.

Partial Exhaust Recirculation

In some processes, a portion of the exhaust air (after being cleaned by cyclones or bag filters) can be recirculated back into the heater. This is particularly effective in closed-loop nitrogen systems.

4. Insulation and Leak Prevention

It sounds basic, but “thermal leaks” are a silent profit killer.

- High-Spec Insulation: Ensure the drying chamber, hot air ducts, and air heater are insulated with high-density mineral wool or ceramic fiber. If the outer shell feels hot to the touch, you are losing money.

- Seal Integrity: Inspect gaskets on manholes, sight glasses, and duct joints. Cold air leaking into the dryer (air infiltration) forces the heater to work harder to maintain the setpoint.

5. Humidity Control of Intake Air

The moisture content of the ambient air fluctuates with the seasons.

- The Problem: On humid monsoon days, the air has less “capacity” to take up moisture, requiring more energy to achieve the same drying result.

- The Solution: Installing a de-humidification system on the intake or using Mass Flow Meters to adjust air volume based on real-time humidity can stabilize energy use year-round.

6. Efficient Atomization & Air Distribution

The way the slurry is dispersed affects how efficiently the air transfers heat.

- Variable Frequency Drives (VFDs): All motors—including the high-speed centrifugal atomizer and the intake/exhaust fans—should be equipped with VFDs. This allows the system to scale energy use to match actual production rates rather than running at 100% capacity constantly.

- Optimized Air Dispersers: A poorly designed air disperser creates “dead zones” in the chamber. AKSH Engineering uses computational fluid dynamics (CFD) to ensure uniform air-droplet contact, preventing wasted heat.

7. Operational Best Practices

| Strategy | Impact | Effort |

| Scheduled Descaling | Improves heat transfer in the air heater. | Medium |

| Bag Filter Maintenance | Reduces pressure drop, lowering fan power consumption. | Low |

| Continuous vs. Batch | Minimizes heat-up and cool-down cycles. | High |

Summary: The AKSH Engineering Checklist

To turn your spray dryer into an energy-efficient powerhouse, follow these five pillars:

- Concentrate the feed to the maximum pumpable limit.

- Insulate every square inch of the hot-zone.

- Recover exhaust heat using high-efficiency exchangers.

- Automate with VFDs and PLC controls to eliminate human error.

- Audit your system annually for air leaks and thermal losses.

At AKSH Engineering Systems Pvt. Ltd., we don’t just build dryers; we engineer thermal solutions that help your business stay competitive in a high-cost energy market.