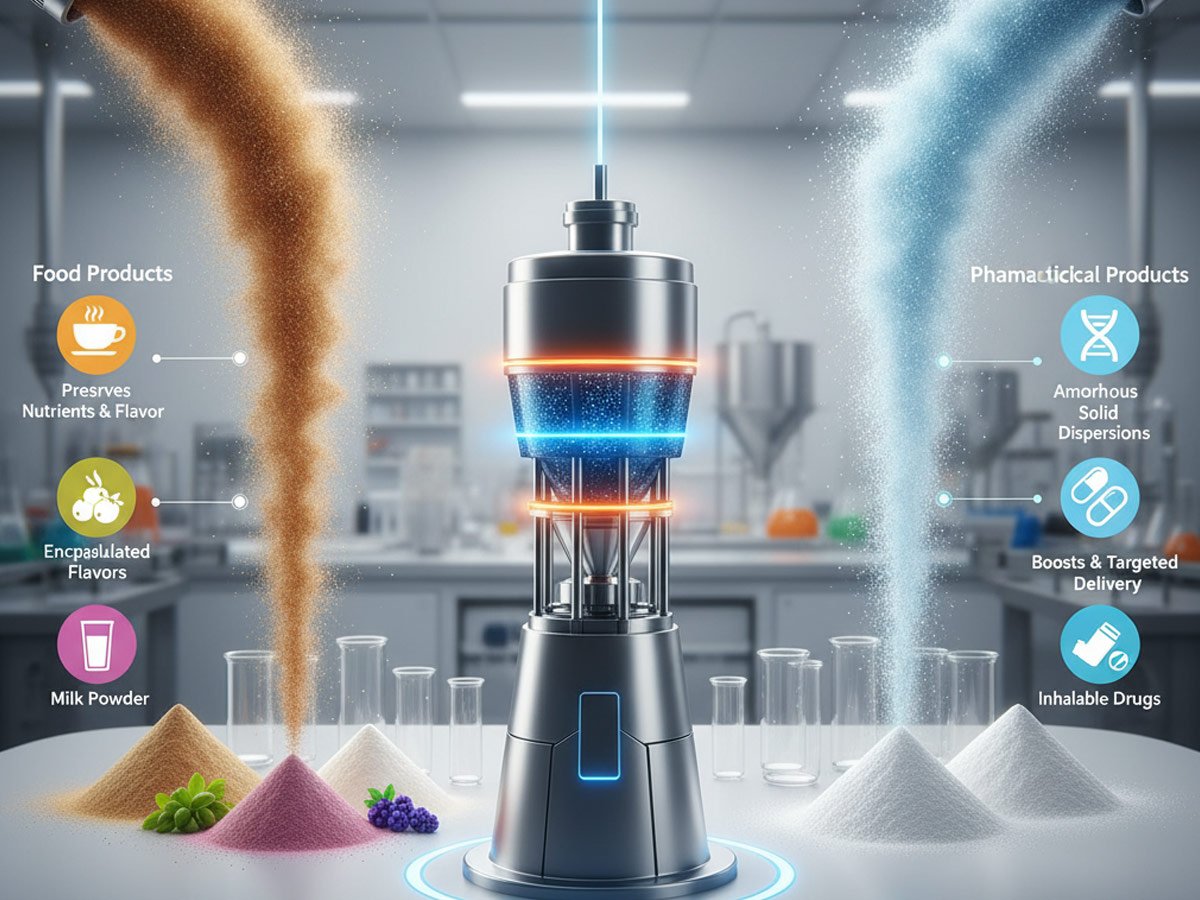

Pharmaceutical Products: Enhancing Drug Efficacy and Delivery

Spray drying is a critical tool for modern drug formulation, enabling the creation of advanced dosage forms, especially for complex or sensitive compounds.

- 1. Bioavailability Enhancement (Solubility):

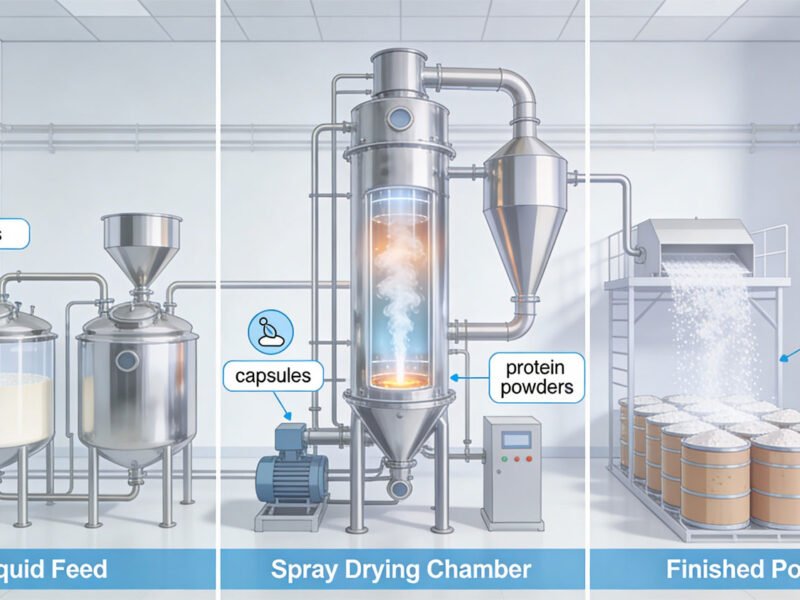

- The Revolution: It allows manufacturers to formulate Amorphous Solid Dispersions (ASDs), which significantly increase the solubility and dissolution rate of poorly soluble drugs. This means the drug can be absorbed more effectively by the body, improving its therapeutic effect.

- 2. Particle Engineering for Drug Delivery:

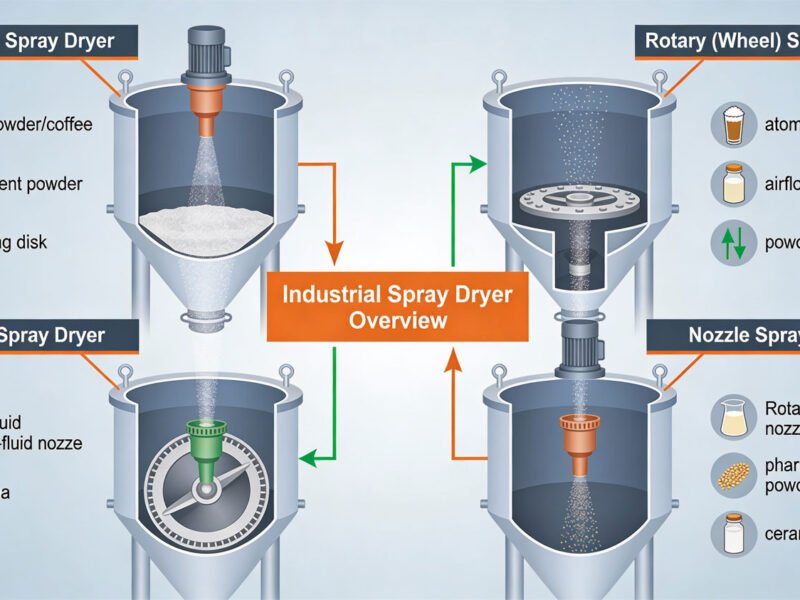

- The Revolution: The process offers unparalleled control over particle size, shape (morphology), and density. This is vital for specialized drug delivery systems:

- Inhalable Powders: Producing extremely fine, uniform particles suitable for Dry Powder Inhalers (DPIs) for treating respiratory conditions.

- Controlled Release: Creating microparticles or microcapsules that encapsulate the drug, enabling it to be released slowly or at a specific site in the body.

- The Revolution: The process offers unparalleled control over particle size, shape (morphology), and density. This is vital for specialized drug delivery systems:

- 3. Stability and Shelf Life:

- The Revolution: Converting sensitive active pharmaceutical ingredients (APIs), including biopharmaceuticals (like vaccines and antibodies), into a dry powder form dramatically increases their stability and shelf life compared to liquid forms, reducing the need for cold-chain storage.

- 4. Efficiency and Cost Reduction:

- The Revolution: It combines particle formation and drying into a single, continuous step, reducing the number of unit operations, increasing production efficiency, and lowering manufacturing costs compared to traditional methods like freeze-drying (lyophilization).

Food Products: Preserving Quality and Driving Innovation

In the food industry, spray drying is essential for preservation, taste encapsulation, and creating convenient ingredients.

- 1. Preservation of Nutrients and Flavor:

- The Revolution: Due to the rapid, short-duration drying (seconds), the product is exposed to heat for a minimal time. This preserves the color, flavor, and nutritional content (especially for heat-sensitive vitamins and proteins) better than many other drying methods.

- 2. Flavor Encapsulation and Protection:

- The Revolution: Spray drying is the primary method for microencapsulating volatile flavor compounds, essential oils, and nutraceuticals (like probiotics and vitamins). This process:

- Protects the ingredients from degradation due to oxygen, light, and moisture.

- Locks in the aroma until the product is rehydrated or consumed.

- The Revolution: Spray drying is the primary method for microencapsulating volatile flavor compounds, essential oils, and nutraceuticals (like probiotics and vitamins). This process:

- 3. Creating Convenient, Instant Products:

- The Revolution: It produces powders with enhanced solubility and dispersibility. This is the core technology behind popular instant products:

- Instant Coffee and Tea

- Powdered Milk, Whey Protein Concentrate (WPC), and Creamers

- Powdered Juices, Sauces, and Soup Mixes

- The Revolution: It produces powders with enhanced solubility and dispersibility. This is the core technology behind popular instant products:

- 4. Functional and Plant-Based Ingredients:

- The Revolution: It plays a key role in the rapidly growing plant-based protein sector, converting liquid plant extracts (from peas, fava beans, etc.) into stable, easy-to-mix protein powders.